JCX 1100 russia arc glazed tile roll forming machine for roof

Basic Info

Model No.: JCX--4kw cnc 1000 glazed tile machine

Product Description

1.Technical parameters:

1.Technical parameters: | Name | Value |

| Brand | JCX |

| Model | JCX-4KW CNC 1000 glazed tile machine |

| Production Capacity | 8-10M/MIN |

| Automatic Grade | FULLY AUTOMATIC |

| Voltage | 220V/380/410/440V |

| Power | 4KW depend on different profile |

| Place of Origin | Botou,China |

| Year | 2013 |

| Certification | N/A |

| Dimension(L*W*H) | 6500mm*1550mm*1510mm |

| Weight | 5-7ton |

| Warranty | One year warranty maintenance free life |

Suitable material | GI,PPGI,AL | |

Thickness of raw material | 0.3—0.8mm | |

Yield strength of material | 235-550Mpa | |

Working Speed | about 4-6m/min | |

Step distance | adjustable according to requirement (>=250mm) | |

Power Requirement | Main motor power: | 11Kw (Depend on final design) |

Hydraulic station power: | 11Kw (Depend on final design) | |

Uncoiler's loading capacity | Max. Capacity: 5000kgs (can be increased to be 10T) | |

Controlling system | Mitsubishi PLC & converter | |

Machine's size | about 12200mm*1650mm*1510mm (Depend on final design) | |

NO | Name | Unit | Qty |

1 | Man-made decoiler | set | 1 |

2 | Main machine for roll forming | set | 1 |

3 | Control system | set | 1 |

4 | Hydraulic system | set | 1 |

JCX 1000 glazed tile colored roll forming machine

JCX 1000 glazed tile colored roll forming machine | Production Description |

|

|

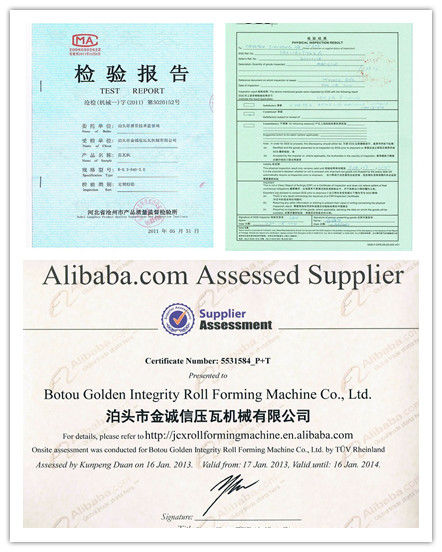

Material of main equipment: Roller material: high grade NO.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm. Active shaft material: high grade NO.45 carbon wrought steel at diameter 72mm. Cutting blade: Cr12 mould steel with quenched treatment. They are widely used as the roof of garden like factory, hotel, exhibition center, villa, civil construction, etc. Features of the production line 1)Professional designing for manufactures roofing & walling 2)Automatically continually manufactures high quality product with PLC. 3)Easy operation : Directly input the data on the touchable screen. 4)Customers decide the profile of products. 5)Saving time and cost owing to high speed running with hydraulic system. 6)One year warranty. Our certification:

Material of main equipment: Roller material: high grade NO.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm. Active shaft material: high grade NO.45 carbon wrought steel at diameter 72mm. Cutting blade: Cr12 mould steel with quenched treatment. They are widely used as the roof of garden like factory, hotel, exhibition center, villa, civil construction, etc. Features of the production line 1)Professional designing for manufactures roofing & walling 2)Automatically continually manufactures high quality product with PLC. 3)Easy operation : Directly input the data on the touchable screen. 4)Customers decide the profile of products. 5)Saving time and cost owing to high speed running with hydraulic system. 6)One year warranty. Our certification:  Company Information We have been established in 1995 as a professional manufacturer of ROLL FORMING MALCHINE. We use AUTO CAD design software. With more than 10 years of experience and strict quality control, our products meet International Standard. We are the leading manufacturer of roll forming machine in China.

Company Information We have been established in 1995 as a professional manufacturer of ROLL FORMING MALCHINE. We use AUTO CAD design software. With more than 10 years of experience and strict quality control, our products meet International Standard. We are the leading manufacturer of roll forming machine in China.  FAQ Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details For the slitting line and cut-to-length: the material type(HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers(only for slitting line), steel plate required cutting length(only for cut-to-length line) For the C,Z,W Profile and roof/wall panel roll forming machine: the material thickness range, width range and the profile drawing are required(how many roll forming stands required are depended on the profile drawing) For the HVAC machine and the stainless steel pipe machine: the wall thickness range and the diameter range of the pipe Pls also provide us with your special requirements for the machine, for example, you want the machine to be a full-automatic one or semi-automatic one in order to save your procurement budget. Q: How can we be assured that you will deliver us quality machine with spare parts? A: We usually require our customers to send the technical people to our factory for checking the quality of the machine before shipping. Considering that the buyer usually is not very familiar with the machine assembling and debugging, so we send the technicians to the buyer`s factory for the installation of the machine provided that the Price Term was conclude on ALL IN basis. In additon, We provide all of our customers with the aftersales-service, its free of charge during the warranty period Q: What do you mean by the ‘ALL IN PRICE’ as you stated in the quotation file? A: The ALL IN Price means the quoted price including below items vaule The complete set of Machine value which covers the spare parts and the moulds if any The machine packing and the container loading charges The after-sales service charge for 5% of the machine value The charges for the machine installation at your factory, we send the technician to your factory free of charge The ALL IN Price not including below items The flight ticket back and forth from China to Your country for our engineer or technician to supply the installation service at your factory, and the all of the transportation charges outside of China as well The expenses of hotel room and foods for our engineer or technicians are not included in the ALL IN Price, which shall be covered by your party The installation needed materials are belong to the buyer self arrangement items, such as the power supply switch; electrical wire , cable and insulating strung wire piping; air-supply system, air origin Q=0.9stere meters/MIN, P=0.8MPa; gear oil, hydraulic oil; track steel(24kg light track); deep protective barrier. Q: What is the process for working with the customerized machine? A: We would encourage you to call or email us so we can explore how we can work together. The order processing procedure usually could be like follows Inquiry offered by the buyer The sales representative acquire the detailed machine technical info from the buyer the technical information is sent from the sales dept. to the technical dept. for studying and work out the machine plan and value the sales representative get the quotation from the technical dept and send to the buyer the buyer is welcomed to ask for some amendments on the machine plan according to his best idea the machine plan keep improving until the buyer is satisfied contract signing and the buyer is requested to make the deposit for 30% of the total value the contracted machine starts production the buyer is requested to come to the seller`s factory to check the machine quality the buyer is requested to pay for the 70% balanced machine value if the checking result is satisfactory container shipping for the machine the seller send the technicians to the buyer`s factory for the installation of the machine and ensure the machine is running well Q: Can you make the machine according to my design or prototype?

FAQ Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details For the slitting line and cut-to-length: the material type(HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers(only for slitting line), steel plate required cutting length(only for cut-to-length line) For the C,Z,W Profile and roof/wall panel roll forming machine: the material thickness range, width range and the profile drawing are required(how many roll forming stands required are depended on the profile drawing) For the HVAC machine and the stainless steel pipe machine: the wall thickness range and the diameter range of the pipe Pls also provide us with your special requirements for the machine, for example, you want the machine to be a full-automatic one or semi-automatic one in order to save your procurement budget. Q: How can we be assured that you will deliver us quality machine with spare parts? A: We usually require our customers to send the technical people to our factory for checking the quality of the machine before shipping. Considering that the buyer usually is not very familiar with the machine assembling and debugging, so we send the technicians to the buyer`s factory for the installation of the machine provided that the Price Term was conclude on ALL IN basis. In additon, We provide all of our customers with the aftersales-service, its free of charge during the warranty period Q: What do you mean by the ‘ALL IN PRICE’ as you stated in the quotation file? A: The ALL IN Price means the quoted price including below items vaule The complete set of Machine value which covers the spare parts and the moulds if any The machine packing and the container loading charges The after-sales service charge for 5% of the machine value The charges for the machine installation at your factory, we send the technician to your factory free of charge The ALL IN Price not including below items The flight ticket back and forth from China to Your country for our engineer or technician to supply the installation service at your factory, and the all of the transportation charges outside of China as well The expenses of hotel room and foods for our engineer or technicians are not included in the ALL IN Price, which shall be covered by your party The installation needed materials are belong to the buyer self arrangement items, such as the power supply switch; electrical wire , cable and insulating strung wire piping; air-supply system, air origin Q=0.9stere meters/MIN, P=0.8MPa; gear oil, hydraulic oil; track steel(24kg light track); deep protective barrier. Q: What is the process for working with the customerized machine? A: We would encourage you to call or email us so we can explore how we can work together. The order processing procedure usually could be like follows Inquiry offered by the buyer The sales representative acquire the detailed machine technical info from the buyer the technical information is sent from the sales dept. to the technical dept. for studying and work out the machine plan and value the sales representative get the quotation from the technical dept and send to the buyer the buyer is welcomed to ask for some amendments on the machine plan according to his best idea the machine plan keep improving until the buyer is satisfied contract signing and the buyer is requested to make the deposit for 30% of the total value the contracted machine starts production the buyer is requested to come to the seller`s factory to check the machine quality the buyer is requested to pay for the 70% balanced machine value if the checking result is satisfactory container shipping for the machine the seller send the technicians to the buyer`s factory for the installation of the machine and ensure the machine is running well Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us Q: What do you need to know so that I can have a machine plan from you for our technical people reference?

A: Well, as the basic needed information for designing a machine plan, pls see below details

For the slitting line and cut-to-length: the material type(HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers(only for slitting line), steel plate required cutting length(only for cut-to-length line)

For the C,Z,W Profile and roof/wall panel roll forming machine: the material thickness range, width range and the profile drawing are required(how many roll forming stands required are depended on the profile drawing)

For the HVAC machine and the stainless steel pipe machine: the wall thickness range and the diameter range of the pipe

Pls also provide us with your special requirements for the machine, for example, you want the machine to be a full-automatic one or semi-automatic one in order to save your procurement budget.

Q: How can we be assured that you will deliver us quality machine with spare parts?

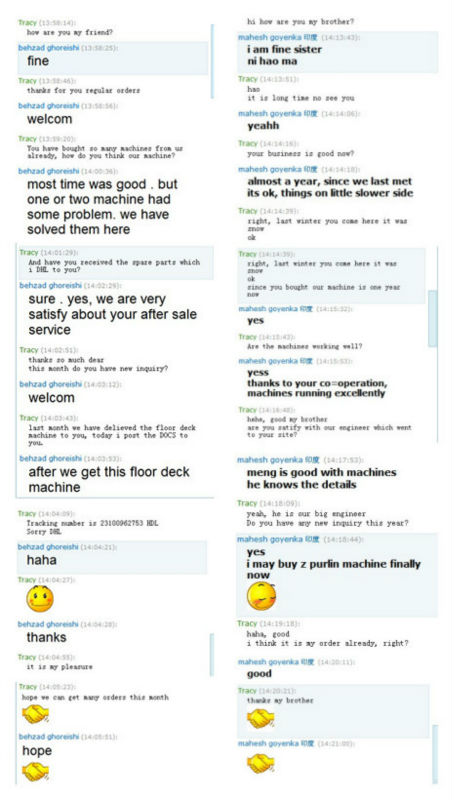

A: We usually require our customers to send the technical people to our factory for checking the quality of the machine before shipping. Considering that the buyer usually is not very familiar with the machine assembling and debugging, so we send the technicians to the buyer`s factory for the installation of the machine provided that the Price Term was conclude on ALL IN basis. In additon, We provide all of our customers with the aftersales-service, its free of charge during the warranty period Buyer Feedback

Contact us if you need more details on Arc Glazed Tile Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Tile Making Machine、Zhejiang Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Arc Glazed Tile Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Tile Making Machine、Zhejiang Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Glazed Tile Sheet Roll Forming Machine

Premium Related Products