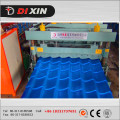

Colour Coated Zinc Roofing Sheet Molding Machine

Basic Info

Model No.: 1000

Product Description

Model NO.: 1000 Certification: SGS, CE, ISO Customized: Customized Transmission Method: Hydraulic Pressure Color: Blue Dimensions: 6.5*1.3*1.1m Thickness: 0.3-0.9mm Productivity: 10m-15m/Min Voltage: 380V 50Hz Specification: 1000 HS Code: 84552210 Tile Type: Colored Steel Condition: New Usage: Roof, Wall, Floor Name: Metal Roofing Sheet Corrugating Iron Sheet Roll Fo Suitable to Process: Color Steel Plate Power: 8kw Cutting Blade: 0.3-0.9mm Diameter of The Roller: 76mm Trademark: dixin Origin: Botou Hebei Metal Roofing Sheet Corrugating Iron Sheet Roll Forming Making Machine

Introduction and Guarantee :

1. This machine contains our experiences in 30 years and many times improvements by our engineers.

2. In our service, we support the equipments and profiles that customers really need and including our most sincere recommends.

3. Our roll forming machines are driven by chain in hydraulic system. Chain Drive System can save the power compare with other system. That also means that customers do not need to pay the extra power fee during production of steel panel.

Applications:

Specifications:

Advantage:

1. We use Automatic control software to manage productive information.

2. Thanks to the High integrated network, the whole automatic control system has an improvement in automaticity.

3. High performance in operation, maintenance, and debugging. Easy to load and unload.

4. First in quality

5. First in time

6. First in price

7. First in services

Contact us if you need more details on Roll Forming Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Tile Making Machine、Cold Rolling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Introduction and Guarantee :

1. This machine contains our experiences in 30 years and many times improvements by our engineers.

2. In our service, we support the equipments and profiles that customers really need and including our most sincere recommends.

3. Our roll forming machines are driven by chain in hydraulic system. Chain Drive System can save the power compare with other system. That also means that customers do not need to pay the extra power fee during production of steel panel.

Applications:

| Construction | Food Services | Lawn & Garden | Shelving |

| Automotive | Fencing | Lighting | Store Fixture |

| Display Industry | Furniture | Material Handling | Sporting Goods |

| Farming | HVAC | Mining | Transportation.etc |

Specifications:

| Suitable to process | colored steel plate, galvanized board |

| Valid width | 840mm |

| Rollers | 14groups |

| Rolling material | Forging steel 45# |

| Rolling galvanization thickness | 0.3-0.9mm |

| Material of the cutting blade | Cr12mov |

| Dimensions | Approx7m*1.8m*1.2m |

| Power | 5.5kw |

| Thickness of the plate | 0.3-0.9mm |

| productivity | 10m-15m/min |

| Diameter of the roller | 76mm |

| Weight | About 6T |

| Voltage | 380V 50Hz |

| Processing precision | Within 1.00mm |

| Equipment components | Man-made uncoiler,roll forming machine, Compture control system Hydraulic control system Press foming cutting |

| Transportation | One complete equipment need one 40 feet container to hold |

Advantage:

1. We use Automatic control software to manage productive information.

2. Thanks to the High integrated network, the whole automatic control system has an improvement in automaticity.

3. High performance in operation, maintenance, and debugging. Easy to load and unload.

4. First in quality

5. First in time

6. First in price

7. First in services

Contact us if you need more details on Roll Forming Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roof Tile Making Machine、Cold Rolling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Customerized Special Design Forming Machine Line

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine