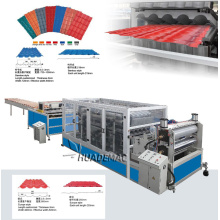

Dx High Quality Glazed Tile Cold Roll Forming Machine

Basic Info

Model No.: 1100-183-24

Product Description

Model NO.: 1100-183-24 Certification: SGS, CE, ISO, CE, SGS Customized: Customized Transmission Method: Machinery Payment: Tt Effective Width: 1100mm Main Motor Power: 4kw Forming Step: 13 Steps Main Frame: 300h Steel Transport Package: No Origin: Cangzhou City, Hebei Province, China Tile Type: Colored Steel Condition: New Usage: Roof, Wall, Floor Warranty: 2 Years Feeding Width: 1250mm Material Thickness: 0.3-0.8mm Hydraulic Pump Power: 4kw Diameter of Shaft: 75mm Trademark: DIXIN Specification: CE SGS HS Code: 84552210 After-Sale Service

Professional Engineers are available to be sent to the customer's factory to install and debug the machines and teach the staff how to operate the machines.

1. Machine name: DX High quality Glazed tile Cold Roll Forming Machine

2. Machine parameters:

3. Work flow:

manual uncoiler-- Roll Forming Machine-- PLC control box-- hydraulic system-- post cut-- output table

4. Specific description

(1) Manual decoiler

Un-powered, single head, max capacity: 5000kg

(2) hydraulic pump station

It is controlled by gear wheel oil pump, after filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutting machine to begin the cutting job.

(3) Computer control cabinet

It adopts TaiDa PLC to control, the target sheet length is adjustable.

Computed mode has two modes: Automatic and manual.

Touch screen.

(4) Output table

It is used to load the finished sheet. This kind is convenient for shipment.

(5) Spare parts

Contact us if you need more details on Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Double Deck Roll Forming Machine、Roof Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Professional Engineers are available to be sent to the customer's factory to install and debug the machines and teach the staff how to operate the machines.

1. Machine name: DX High quality Glazed tile Cold Roll Forming Machine

2. Machine parameters:

| 1 | material of input sheet | galvanized steel/ colored steel |

| 2 | feeding width | 1250mm |

| 3 | effective width | 1100mm |

| 4 | material thickness | 0.3-0.8mm |

| 5 | main motor power | 4kw |

| 6 | hydraulic pump power | 4kw |

| 7 | forming step | 13 steps |

| 8 | diameter of shaft | 75mm |

| 9 | main frame | 300H steel |

| 10 | roller material | 45# steel with chrome |

| 11 | cutting knives material | Cr12 |

| 12 | machine size | 7.0*1.5*1.5m |

| 13 | machine weight | about 4 tons |

3. Work flow:

manual uncoiler-- Roll Forming Machine-- PLC control box-- hydraulic system-- post cut-- output table

4. Specific description

(1) Manual decoiler

Un-powered, single head, max capacity: 5000kg

(2) hydraulic pump station

It is controlled by gear wheel oil pump, after filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutting machine to begin the cutting job.

(3) Computer control cabinet

It adopts TaiDa PLC to control, the target sheet length is adjustable.

Computed mode has two modes: Automatic and manual.

Touch screen.

(4) Output table

It is used to load the finished sheet. This kind is convenient for shipment.

(5) Spare parts

| No. | Name | Unit | Qty |

| 1 | Manual decoiler | set | 1 |

| 2 | Main Forming Machine | set | 1 |

| 3 | PLC control system | set | 1 |

| 4 | Hydraulic pump station | set | 1 |

| 5 | Post cut | set | 1 |

| 6 | Electric motor | set | 1 |

| 7 | Output table | set | 1 |

Product Categories : Glazed Tile Roll Forming Machine

Premium Related Products

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine