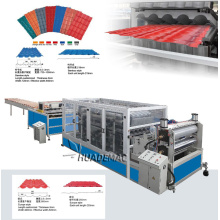

Dx Cheap Metal Roofing Roll Forming Machine

Basic Info

Model No.: DX 1250-1050-210-25

Product Description

Model NO.: DX 1250-1050-210-25 Condition: New Usage: Roof Type: Rolling Machine Feature: Automation Warranty: 12 Months Mode: 1050-210-25 Tile Feeding Material: Metal Coil Trademark: DIXIN Origin: China, Hebei Certification: SGS, CE, ISO9001 Customized: Customized Transmission Method: Machinery Power Source: Electric Advantage: Easy to Maintenance Forging Forming Method: Mold Forging Auto: Fully Automatic Feeding Width: 1000mm Specification: CE SGS ISO HS Code: 84552210 1050 Metal Roofing Machine Making

Quick detailes:

1 Direct factory in China

2 Plc control system Roll Forming Machine

3 Ce certificated

4 Forming speed: 6-8m/min

5 Hot sale. One machine produce four kinds of profiles

2. Technique parameters

(1) processing material: Aluzinc/galvanized steel/colored Steel Coil

(2) material thickness: 0.3-0.8mm

(3) effective width: 840mm

(4) feeding width: 1000mm

(5) main motor power: 4 kw

(6) pump power: 4 kw

(7) shaft diameter: 75 mm

(8) forming steps: 11 steps

(9) roller material: 45# forged steel, with hard chrome plating

(10) main frame: 300h steel

(11) medium plate thickness: 16mm

(12) control systerm: Plc computer control with inverter

(13) power supply: 380v, 3 phase, 60hz or as your requirement

(14) 0veral sized: 6500mm*1500mm*1500mm

Packing size: 5.7m*1.6m*1.5m(l*w*h), 3.2 tons

3. One manual uncoiler for free and other accessary

4. Loading in a 20 foot container.

5. Service.

Engineer overseas service available

6 Rules of roll forming

The material being formed must use the same length at each forming operation. If the length of material varies from one forming operation to another, unnecessary stresses can build up causing problems such as ripples, herringboning and double bending.

Stresses in the formed elements and the sheet edges must be well within the yield stress of the material. Stress levels above the yield stress will cause the material to increase in length and subsequently create either a wave on the strip edge, or cause the section to curve away from the stressed edge where the two edges are turned up. In the case of a section with one up-turned edge and one down-turned edge, the stress will manifest as a twist along the length of the sheet. On thinner materials high stresses usually manifest themselves as a herringbone effect.

The material spring back must be allowed for by over bending. Unless an allowance is made for spring back the outer forms will lie back, and where humps or similar are formed in the centre of the section the overall cover width will expand.

The neutral axis must be used wherever possible. Forming on the neutral axis creates equal stresses of a lower order than base line forming and will produce a level section on exiting the forming process. Base line forming on higher sided profiles will normally create a downward curve in the sheet.

The peripheral speed of the roll contact faces should be constant within a small tolerance. When the peripheral speed of a roll varies to that of the linear speed of the section being formed scuffing will occur. This will result in damage to the surface of the material and reduced roll life. Opening up the gap between top and bottom rolls to reduce the scuffing will cause malformation of the profile.

The line of the form over the forming stations must be convex. If a line taken over the tops of the push up rolls over the forming stations does not form a convex shape, the leading edge of the sheet passing over the final form roll will lift clear of the intermediate form rolls. This lifting will cause increased stresses in the sheet at the final rolls.

When a roll pushes up a bend there should be a corresponding roll to bend about. When a form roll pushes on the section, if there is not a roll for it to bend about the form will take the easiest route, usually bending the section away from the roll. Contact us if you need more details on Metal Roofing Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Metal Roofing Machine、Metal Tile Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Quick detailes:

1 Direct factory in China

2 Plc control system Roll Forming Machine

3 Ce certificated

4 Forming speed: 6-8m/min

5 Hot sale. One machine produce four kinds of profiles

2. Technique parameters

(1) processing material: Aluzinc/galvanized steel/colored Steel Coil

(2) material thickness: 0.3-0.8mm

(3) effective width: 840mm

(4) feeding width: 1000mm

(5) main motor power: 4 kw

(6) pump power: 4 kw

(7) shaft diameter: 75 mm

(8) forming steps: 11 steps

(9) roller material: 45# forged steel, with hard chrome plating

(10) main frame: 300h steel

(11) medium plate thickness: 16mm

(12) control systerm: Plc computer control with inverter

(13) power supply: 380v, 3 phase, 60hz or as your requirement

(14) 0veral sized: 6500mm*1500mm*1500mm

Packing size: 5.7m*1.6m*1.5m(l*w*h), 3.2 tons

3. One manual uncoiler for free and other accessary

4. Loading in a 20 foot container.

5. Service.

Engineer overseas service available

6 Rules of roll forming

The material being formed must use the same length at each forming operation. If the length of material varies from one forming operation to another, unnecessary stresses can build up causing problems such as ripples, herringboning and double bending.

Stresses in the formed elements and the sheet edges must be well within the yield stress of the material. Stress levels above the yield stress will cause the material to increase in length and subsequently create either a wave on the strip edge, or cause the section to curve away from the stressed edge where the two edges are turned up. In the case of a section with one up-turned edge and one down-turned edge, the stress will manifest as a twist along the length of the sheet. On thinner materials high stresses usually manifest themselves as a herringbone effect.

The material spring back must be allowed for by over bending. Unless an allowance is made for spring back the outer forms will lie back, and where humps or similar are formed in the centre of the section the overall cover width will expand.

The neutral axis must be used wherever possible. Forming on the neutral axis creates equal stresses of a lower order than base line forming and will produce a level section on exiting the forming process. Base line forming on higher sided profiles will normally create a downward curve in the sheet.

The peripheral speed of the roll contact faces should be constant within a small tolerance. When the peripheral speed of a roll varies to that of the linear speed of the section being formed scuffing will occur. This will result in damage to the surface of the material and reduced roll life. Opening up the gap between top and bottom rolls to reduce the scuffing will cause malformation of the profile.

The line of the form over the forming stations must be convex. If a line taken over the tops of the push up rolls over the forming stations does not form a convex shape, the leading edge of the sheet passing over the final form roll will lift clear of the intermediate form rolls. This lifting will cause increased stresses in the sheet at the final rolls.

When a roll pushes up a bend there should be a corresponding roll to bend about. When a form roll pushes on the section, if there is not a roll for it to bend about the form will take the easiest route, usually bending the section away from the roll. Contact us if you need more details on Metal Roofing Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Metal Roofing Machine、Metal Tile Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Glazed Tile Roll Forming Machine

Premium Related Products

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine