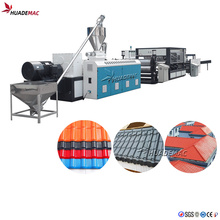

corrugated roll forming machinery

Basic Info

Model No.: 780

Product Description

Welcome to view JCX Corrugated Roll Forming Machine according to customers requirements ,custom Roll Forming Machine 1. Commonly Used Drawings

We are not only offer customers a wonderful machine for making, but also the abundant experience, precision making, stable automatic manufacture by hydraulic power, hi-tech control system, and our enthusiasm. 2.Machine parameters Thickness of Forming Sheet: 0.15-0.8 mm.

Forming Speed:10-15 M/min.

Roll Shaft Diameter: 70 mm . Main Motor:5.5kw Hydraulic Motor: 4kw

Roll stands: 12 rows Material of cutting:cr12 Hydraulic:40# Control system: Panasonic PLC Dimension:6.5*1.45*1.5

Complete with uncoiler, hydraulic cutting device and including run-out table.

This machine is controlled by computer system with touch screen. 3.Components of the processing line Manual Decoiler------------------------------1 set(free) Roll Forming Main Station----------------1 set(customer designed) Oil Pump----------------------------------------1 set(customer designed) Control Box-------------------------------------1 set(Panasonic PLC or customer designed) Simple Receiving Table--------------------2 sets(free) 4.Working Process

5.Pictures Show <1>. Manual un-coiler 2) Feeding device:

2) Feeding device:

3)photo of machine

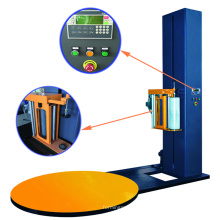

4) Electric control system:

4) Electric control system:  5.Hydraulic system

5.Hydraulic system  6. Our Advantage

6. Our Advantage  7.Packing&Shipping

7.Packing&Shipping  8. Customer Feedback

8. Customer Feedback  12.FAQ ♣ Payment:T/T,L/C,cash. ♣ Payment terms:EXW,C&F,CIF are available. ♣ warranty:one year,we will provide technical support for the machine. ♣ Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us ♣ Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details For the slitting line and cut-to-length: the material type(HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers(only for slitting line), steel plate required cutting length(only for cut-to-length line)

12.FAQ ♣ Payment:T/T,L/C,cash. ♣ Payment terms:EXW,C&F,CIF are available. ♣ warranty:one year,we will provide technical support for the machine. ♣ Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us ♣ Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details For the slitting line and cut-to-length: the material type(HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers(only for slitting line), steel plate required cutting length(only for cut-to-length line)

For the C,Z,W Profile and roof/wall panel roll Forming Machine: the material thickness range, width range and the profile drawing are required(how many roll forming stands required are depended on the profile drawing)

♣ Q: How can we be assured that you will deliver us quality machine with spare parts?

A: We usually require our customers to send the technical people to our factory for checking the quality of the machine before shipping. Considering that the buyer usually is not very familiar with the machine assembling and debugging, so we send the technicians to the buyer`s factory for the installation of the machine provided that the Price Term was conclude on ALL IN basis. In additon, We provide all of our customers with the aftersales-service, its free of charge during the warranty period Contact us if you need more details on Industrial Barrel Corrugated Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Used Metal Roll Forming Machinery、Portable Roll Forming Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Wave height | 35mm |

| Wave length | 130mm |

| Cover width | 780mm |

| Coil width | 1000mm |

| Thickness of material plate | 0.3-0.8mm |

Forming Speed:10-15 M/min.

Roll Shaft Diameter: 70 mm . Main Motor:5.5kw Hydraulic Motor: 4kw

Roll stands: 12 rows Material of cutting:cr12 Hydraulic:40# Control system: Panasonic PLC Dimension:6.5*1.45*1.5

Complete with uncoiler, hydraulic cutting device and including run-out table.

This machine is controlled by computer system with touch screen. 3.Components of the processing line Manual Decoiler------------------------------1 set(free) Roll Forming Main Station----------------1 set(customer designed) Oil Pump----------------------------------------1 set(customer designed) Control Box-------------------------------------1 set(Panasonic PLC or customer designed) Simple Receiving Table--------------------2 sets(free) 4.Working Process

5.Pictures Show <1>. Manual un-coiler

2) Feeding device:

2) Feeding device:

3)photo of machine

4) Electric control system:

4) Electric control system:  5.Hydraulic system

5.Hydraulic system  6. Our Advantage

6. Our Advantage  7.Packing&Shipping

7.Packing&Shipping  8. Customer Feedback

8. Customer Feedback  12.FAQ ♣ Payment:T/T,L/C,cash. ♣ Payment terms:EXW,C&F,CIF are available. ♣ warranty:one year,we will provide technical support for the machine. ♣ Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us ♣ Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details For the slitting line and cut-to-length: the material type(HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers(only for slitting line), steel plate required cutting length(only for cut-to-length line)

12.FAQ ♣ Payment:T/T,L/C,cash. ♣ Payment terms:EXW,C&F,CIF are available. ♣ warranty:one year,we will provide technical support for the machine. ♣ Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us ♣ Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details For the slitting line and cut-to-length: the material type(HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers(only for slitting line), steel plate required cutting length(only for cut-to-length line)For the C,Z,W Profile and roof/wall panel roll Forming Machine: the material thickness range, width range and the profile drawing are required(how many roll forming stands required are depended on the profile drawing)

♣ Q: How can we be assured that you will deliver us quality machine with spare parts?

A: We usually require our customers to send the technical people to our factory for checking the quality of the machine before shipping. Considering that the buyer usually is not very familiar with the machine assembling and debugging, so we send the technicians to the buyer`s factory for the installation of the machine provided that the Price Term was conclude on ALL IN basis. In additon, We provide all of our customers with the aftersales-service, its free of charge during the warranty period Contact us if you need more details on Industrial Barrel Corrugated Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Used Metal Roll Forming Machinery、Portable Roll Forming Machines. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Corrugated Roll Forming Machine

Premium Related Products

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine