HOT!!JCX 760 shutter door rolling machine

Basic Info

Model No.: 760

Product Description

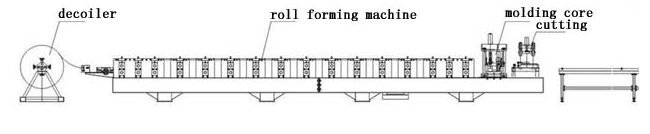

Technical process: The production line are mainly constituted by material entry frame,roll forming machine,automatic shearing mechanism ,hydraulic system,computer control system that adopts imported PLC,high precision length counting system and so on. Work flow: Uncoiling the sheet→sheet guiding→roll forming machine→step forming mechanism→measure length→automatic cutting→panel to the support

Technical process: The production line are mainly constituted by material entry frame,roll forming machine,automatic shearing mechanism ,hydraulic system,computer control system that adopts imported PLC,high precision length counting system and so on. Work flow: Uncoiling the sheet→sheet guiding→roll forming machine→step forming mechanism→measure length→automatic cutting→panel to the support  1.Technical parameters:

1.Technical parameters: No. | main parameter of shutter door roll forming machine | |

1 | Suitable to process | Color steel sheet |

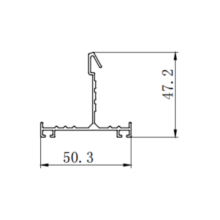

2 | Effective width | 760mm |

3 | Roller steps | 12 rows |

4 | Dimensions | 6m*1m*0.9m (depend on different profile) |

5 | Main Power | 4kw(according customer's requirement) |

6 | Thickness of the plate | 0.6-0.8mm |

7 | Productivity | 5-7m/min |

8 | Coil width | 1000mm |

9 | Weight | About 4 T |

10 | Voltage | 380V 50Hz 3 phases |

11 | Material of the cutting plate | Cr12 |

12 | Hydraulic | 40# |

13 | Processing precision | Within 1.00mm |

14 | Control system | PLC control |

15 | Wave height | 120mm |

16 | Material of roller | Gcr15 steel |

Coil inner-diameter: 508mm (2) Roll-Forming M/C:

Steps:13 Roller Material: 45# steel Voltage:380V/50Hz. line speed:3-6m/min; Rolling chromium thickness:0.05 mm (3) Cutting Mechanism It adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Stop to cut , Post cut cutting length tolerance: ±2mm Cutting tool material: GCr12 with quenched treatment 60-62°C (4) Hydraulic System It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Power of the oil pump: 3kw Hydraulic oil :40# (5)Computer control cabinet : It adopts Taida PLC to control. The target piece length is adjustable and digit of it can be adjusted Computed mode has two modes: automatic and manual one. (6)Counter : One counter gauges length, pulses, and decides length (7) Output table It used to load the forming plate 3.Features of the production line •Low cost •High efficiency •Reliable working •Low energy consumption

1.Delivery date: 30days after receiving deposit. 2.Packing: Main machine is nude,the computer control box is packed by wooden carton box. 3.Sales clause: you should pay 30% of the total payment on the order day, after signing, you can send person to inspect goods, then payoff the whole payment before shipping out the goods. 4.Guarantee:In correct operation and maintenance, the machine is one year guarantee since leaving the seller’s factory. 5.Installation: If buyer need, the seller will send one or two technician to the buyer's factory to install & testing the machine, the buyer will assist the seller’s technician to get the visa and pay for the two-way flight tickets and local accommodation, visa cost. by the way , buyer pay 50USD/day for technician extra. •Noted:all the parameters can be changed as the customer's requirement,and different machine.

1.Delivery date: 30days after receiving deposit. 2.Packing: Main machine is nude,the computer control box is packed by wooden carton box. 3.Sales clause: you should pay 30% of the total payment on the order day, after signing, you can send person to inspect goods, then payoff the whole payment before shipping out the goods. 4.Guarantee:In correct operation and maintenance, the machine is one year guarantee since leaving the seller’s factory. 5.Installation: If buyer need, the seller will send one or two technician to the buyer's factory to install & testing the machine, the buyer will assist the seller’s technician to get the visa and pay for the two-way flight tickets and local accommodation, visa cost. by the way , buyer pay 50USD/day for technician extra. •Noted:all the parameters can be changed as the customer's requirement,and different machine.

specialized manufacturer of roll forming machine,any requests just mail me.

specialized manufacturer of roll forming machine,any requests just mail me.  EXELLENT QUALITY AND COMPETITIVE PRICE! CHOOSE US , CHOOSE THE BEST! Thank you for your time! Contact us if you need more details on Roof Sheet Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming Machinery、Roof Sheet Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

EXELLENT QUALITY AND COMPETITIVE PRICE! CHOOSE US , CHOOSE THE BEST! Thank you for your time! Contact us if you need more details on Roof Sheet Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Roll Forming Machinery、Roof Sheet Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Shutter Door

Premium Related Products