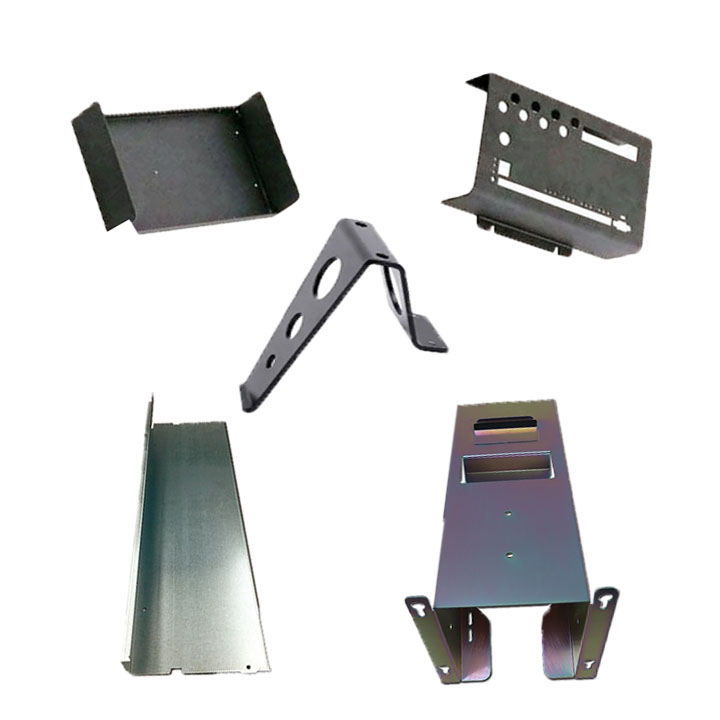

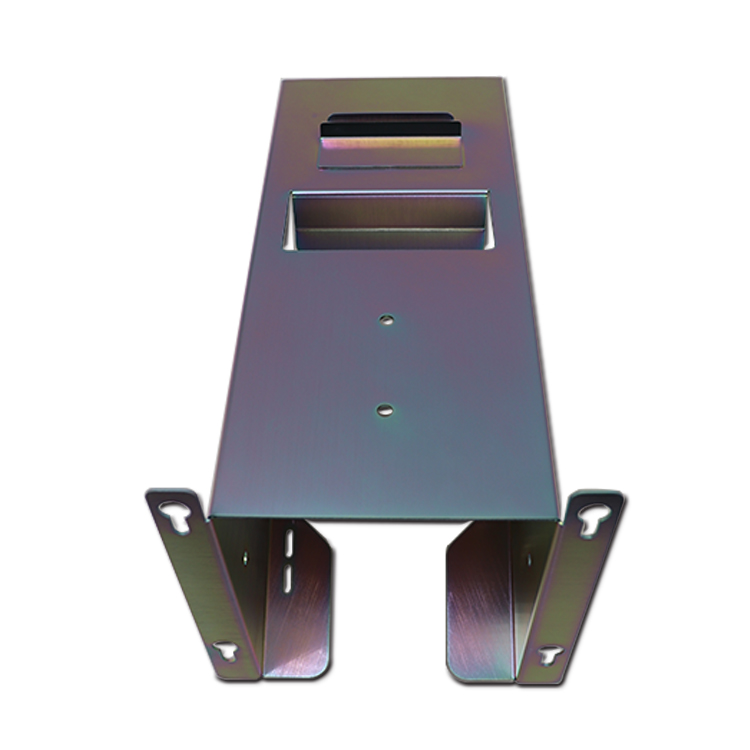

oem odm sheet metal welding fabrication part

Product Description

Sheet metal machining method:

Non die processing: the processing method of sheet metal through digital punching, laser cutting, plate Shearing Machine, Bending Machine, rivet machine and other equipment. It is generally used for sample production or small batch production, with high cost. Short processing cycle and rapid response.

Mold processing: the sheet metal is processed through fixed molds. Generally, there are blanking molds and forming molds, which are mainly used for mass production with low cost. The cost of early mould is high and the quality of parts is guaranteed. The early processing cycle is long and the mold cost is high.

Bending machine is divided into ordinary bending machine and CNC bending machine. Due to the high accuracy requirements and irregular bending shape, the sheet metal bending of communication equipment is generally bent by NC bending machine. Its basic principle is to bend and form the sheet metal parts by using the bending knife (upper die) and V-groove (lower die) of the bending machine. Advantages: convenient clamping, accurate positioning and fast processing speed; Disadvantages: low pressure, can only process simple forming, low efficiency.

Product Details:

According to your drawings (size, material, thickness, processing content, required technology, etc.)

Material: carbon steel, SPCC, SGCC, stainless steel, aluminum, brass, copper, etc

Processing: Laser cutting, precision stamping, bending, CNC punching, grinding, riveting, drilling, welding, and so on

Surface treatment: drawing, polishing, anodizing, powder coating, electroplating, screen printing, sandblasting, etc

Tolerance: ±0.1mm, 100%QC before delivery, can provide quality control table

Size: Accept custom size.

Colors: white, blank, silver, red, gray, Pantone, RAL, etc

Drawing format: DWG, DXF, STEP, IGS, 3DS, STL, SKP, AI, PDF, JPG, draft.

Price terms: EXW, FOB, CIF, DDP, etc

Payment term: Sample: 100% payment before production

Mass production :(50% in advance as deposit, balance before delivery)

Certificate: ISO9001:2015 / SGS

FAQ:

Q1: Are you a factory or a trading company?

A: We are a factory, so we can offer you competitive prices.

Q2: What kind of services do you offer?

A: OEM sheet metal processing, CNC processing, stamping tool manufacturing, etc.

Q3: What information is required for a quotation?

A: In order to quote for you earlier, please provide us with the following information at the time of inquiry.

1. Detailed drawings (STEP,CAD,SOLID Works,DXF,PDF)

2. Material requirements (SUS,SPCC,AL,SECC,SGCC)

3.Surface treatment(powder coating,planting,sand blasting,polishing,oxidization,brushing,etc)

4. Quantity (per order/month/year)

5. Any special requirements or requirements, such as packaging, delivery, labeling, etc.

Q4: What if there are no drawings?

A: Please send your sample to our factory, then we can copy or provide you with a better solution, please send us pictures or sketches with dimensions (thickness, length, height, width), if the order is placed, CAD or 3D files will be made for you.

Why us?

We have many years of experience in sheet metal, CNC processing production, has an advanced sheet metal processing production line, equipped with laser cutting, CNC shear, CNC punching, CNC bending, automatic riveting, automatic welding, automatic spraying, tooling, polishing, screen printing, assembly and another large workshop, has all kinds of advanced testing equipment, perfect testing process.

click request quotation

Product Categories : Sheet Metal Fabrication > Sheet Metal Parts