Hot sale High Speed Cut to length Line Customize Machine All the informations here including the specifications and the product pictures are based on the machine that we've export lately Please have a look for the reference. Product Description 1. Introduction The cutting machine is composed of man-made decoiler, feeding, slitter and recoiler. Its main function is make the wide coil into strips.

cut-to-length line (also known as cut-to-length machine) can meet customer's request of max line speed 60m/min by uncoiling & leveling a coil strip, and then shearing the leveled flat strip to certain length of sheets. The

Steel Coil cut-to-length line has one leveling machine driven by DC or AC motor, and the length-fixing is by encoder. The steel coil cut-to-length line (also known as cut-to-length machine) is composed of: coil loading car, single-mandrel decoiler, coil-head guide, press & shoveling equipment, pinch-feeding, hole accumulator, side guide, leveling machine,final sheet sending out equipment, length-fixing encoder, Hydraulic

Shearing Machine, delivery belt, piling-up bracket, up-down lifting table, moving-out car, hydraulic system and electric control system.

The normal speed steel coil cut-to-length line (also known as cut-to-length machine) fit steel coils with thickness: (0.2-2mm, 0.3-3mm) and changeable width and length of finished sheets depend on customer's practical need. 2.Machine parameters A. Parameter:

1. WIDTH: 0-1500mm;

2. THICKNESS: 0.3-2mm;

3. MANMADE DECOILER: 10T;

4. TOLERANCE: ±0.10mm;

5. SPEED: 0-60m/min;

6. SHAFT: Φ120mm, 40CR;

7. RECOILER INNER DIAMETER: Φ500mm (10T);

8. POWER: 380V, 50HZ, 3PHASES. B. Composition

1. DECOLER: 10t

Hydraulic Decoiler2. Slitter:

Driving: 18.5kw speed adjustable motor with Inverter,reducer,Cardan etc.

3. Main machine:

Adjust framework adopt turbine & scroll.

4. Tension device:

Clincher fix strip.

5. RECOILER:

CORE: Φ500mm×1500mm

BEARING: 10T;

22kw speed adjustable motor with Inverter, hydraulic pump, segregation device.

6. CONTROL BOX:

It adopts PLC to control. The system is easy to operate and use. 3.Pictures Show

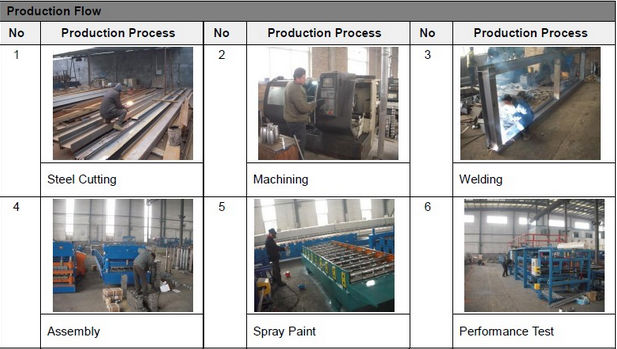

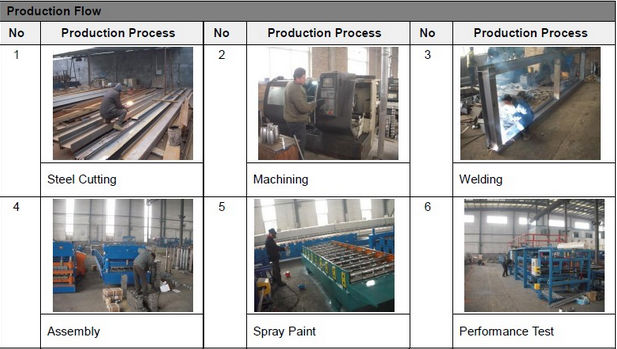

4.Production flow

5.Production Machinry

6.Procurement Aspects

Procurement Aspects | Detailed Rule |

Payment Terms | The payment shall be made by L/C or T/T ( 30% down-payment and the balance for 70% shall be paid before container loading at the seller`s factory when the buyer confirms the quality is up to the contracted requirements. |

packaging | Suitable for sea transportation.Usually one High precision Grape stake roller formed facility loads in one container.Depends on the machine's size and weight. |

Delivery Time | 30-65days. Depends on the machine type. |

After-sales Service | Warranty: 1 year warranty from date of shipment.

Guarantee:

1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of purchase. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 50$ per day shall be for purchaser’s account if manufacturer’s engineer has to be send to purchaser’s factory to maintain the machine during the guarantee period. |

Purchasing Process | fistly, send us the product profile. If it needs punching, please also send us the drawing of holes.

secondly, communicate with our professional salesperson on the technical details.

Thirdly, according to your requirements, our designers match you a right machine, and we will make you a quotation accordingly.

Fourthly, if you think it's necessary, you can visit our factory. In this way, you can see the machine at sght and communicate with our engineers.

fifthly, if you are satisfied with our machine and the price, then we will make the contract with each other officially.

sixthly, according to the contract, you pay the money and we ship the machine to you. |

If you are tired of those Chinese bad machines, and want to buy high quality machines in China, Just stop searching!we are your best choice!We offer you quality machine with good price! Our main products include roll forming machines, guardrail roll forming machines, steel deck forming machines, door & window frame roll forming equipment, steel metal door making lines, guide rail rollforming machines, upright post roll formers, pipe and tube roll formers, purlin cold roll forming machines, T-bar forming machines, grape trellis roll forming machines, roof tile forming machines, steel metal panel roll forming machines, stud and track forming machines, cable tray roll forming machines, shelf rack making machines, gutter roll forming machines, roller shutter manufacturing lines, car bumper forming machines, car door forming machines, distribution cabinet making machines, channel roll forming machines and so on. Mob: +86 18732755439 Skype:presley.xu

Contact us if you need more details on Sheet Cutting to Length Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about High Precision Cut to Length Line、Metal Cut to Length Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Shearing Machine/Bending Machine

4.Production flow

4.Production flow  5.Production Machinry

5.Production Machinry  6.Procurement Aspects

6.Procurement Aspects