High speed double layer roll forming machine with CE,ISO

Basic Info

Model No.: jcx c purlin

Product Description

Product Description

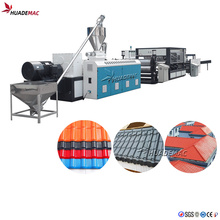

High speed double layer roof panel roll forming mchine with CE,ISO

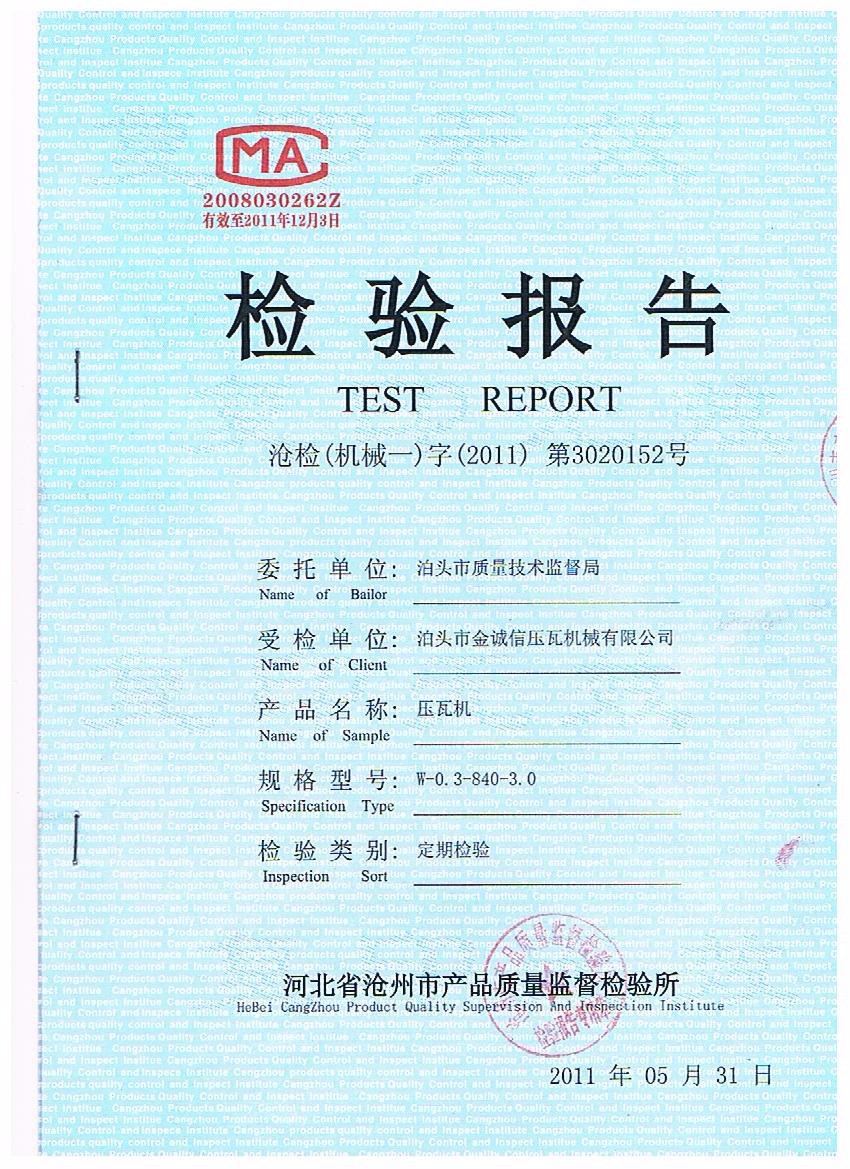

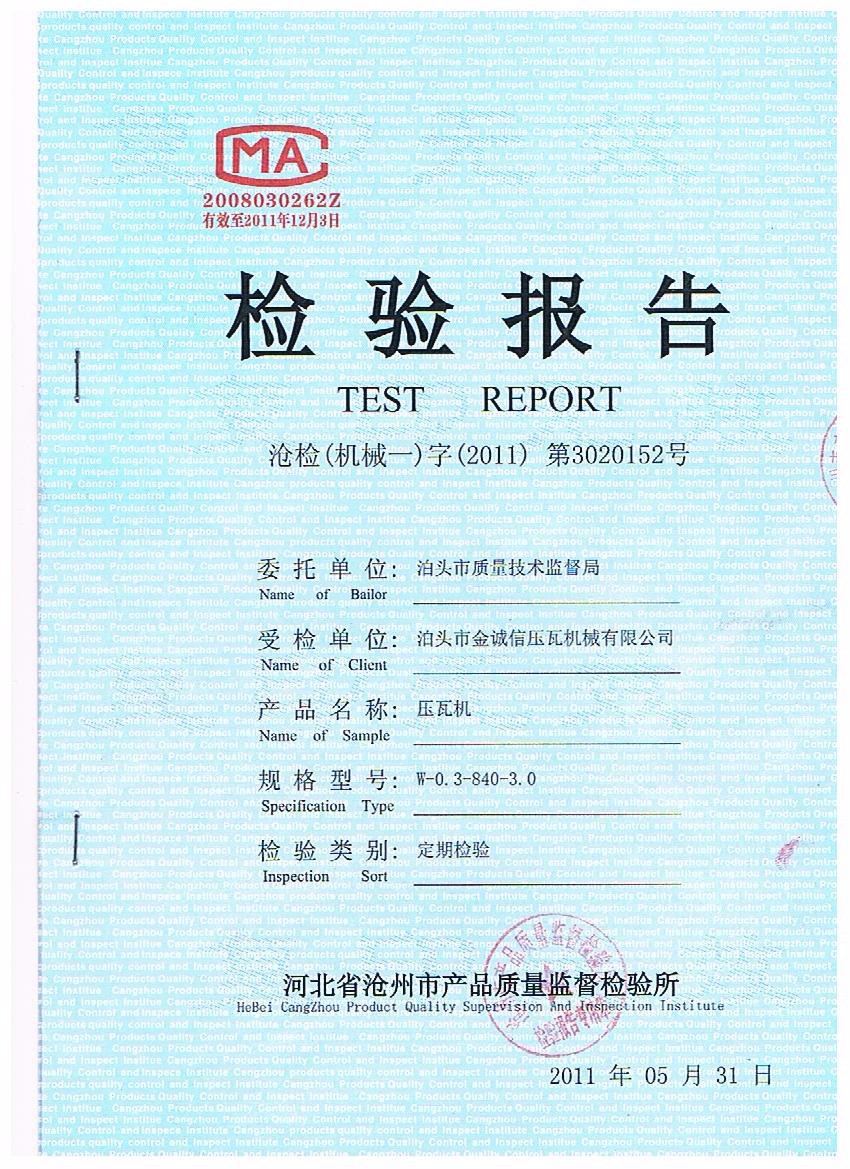

Certifications

Certifications

Detailed Images

Detailed Images  Machine Parts Name: Manual Decoiler Functional and structural characteristics : It is used to support the Steel Coil and uncoil it in a turnable way. The steel coil is uncoiled by hydraulic. The uncoiler can bear 5T. It is suitable to process the coiled steel with the inside diameter of 508mm.

Machine Parts Name: Manual Decoiler Functional and structural characteristics : It is used to support the Steel Coil and uncoil it in a turnable way. The steel coil is uncoiled by hydraulic. The uncoiler can bear 5T. It is suitable to process the coiled steel with the inside diameter of 508mm.

Main Features Name: Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

Power of the oil pump: 4kw;

Hydraulic oil: 40#;.

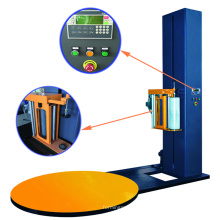

Machine Parts Name: Computer control cabinet

Machine Parts Name: Computer control cabinet

It adopts Panasonic PLC to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

Main Features Name: Runout table

It adopts welded steel and supported roller to transmit the products. There are two frames with the length of 3m/one.

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Packing & Delivery

Related Products

Single layer IBR Roll Forming Machine 91.8% Response Rate Roof Corrugated Roll Forming Machine 91.8% Response Rate Glazed Roof Roll Forming Machine 91.8% Response Rate Contact us if you need more details on Metal Roofing Sheet Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Metal Tile Making Machine、High Quality and Best Price Roofing Sheets. If these products fail to match your need, please contact us and we would like to provide relevant information.

Single layer IBR Roll Forming Machine 91.8% Response Rate Roof Corrugated Roll Forming Machine 91.8% Response Rate Glazed Roof Roll Forming Machine 91.8% Response Rate Contact us if you need more details on Metal Roofing Sheet Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Metal Tile Making Machine、High Quality and Best Price Roofing Sheets. If these products fail to match your need, please contact us and we would like to provide relevant information.

High speed double layer roof panel roll forming mchine with CE,ISO

Certifications

Certifications

Detailed Images

Detailed Images  Machine Parts Name: Manual Decoiler Functional and structural characteristics : It is used to support the Steel Coil and uncoil it in a turnable way. The steel coil is uncoiled by hydraulic. The uncoiler can bear 5T. It is suitable to process the coiled steel with the inside diameter of 508mm.

Machine Parts Name: Manual Decoiler Functional and structural characteristics : It is used to support the Steel Coil and uncoil it in a turnable way. The steel coil is uncoiled by hydraulic. The uncoiler can bear 5T. It is suitable to process the coiled steel with the inside diameter of 508mm.Main Features Name: Hydraulic system

It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job.

Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves.

Power of the oil pump: 4kw;

Hydraulic oil: 40#;.

Machine Parts Name: Computer control cabinet

Machine Parts Name: Computer control cabinet It adopts Panasonic PLC to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

Main Features Name: Runout table

It adopts welded steel and supported roller to transmit the products. There are two frames with the length of 3m/one.

Our Service

Our Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service

Pre-Sales Service * Inquiry and consulting support. * Sample testing support. * View our Factory. After-Sales Service* Training how to instal the machine, training how to use the machine. * Engineers available to service machinery overseas. Packing & Delivery

Single layer IBR Roll Forming Machine 91.8% Response Rate Roof Corrugated Roll Forming Machine 91.8% Response Rate Glazed Roof Roll Forming Machine 91.8% Response Rate Contact us if you need more details on Metal Roofing Sheet Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Metal Tile Making Machine、High Quality and Best Price Roofing Sheets. If these products fail to match your need, please contact us and we would like to provide relevant information.

Single layer IBR Roll Forming Machine 91.8% Response Rate Roof Corrugated Roll Forming Machine 91.8% Response Rate Glazed Roof Roll Forming Machine 91.8% Response Rate Contact us if you need more details on Metal Roofing Sheet Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Metal Tile Making Machine、High Quality and Best Price Roofing Sheets. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Roofing Roll Forming Machine

Premium Related Products

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine