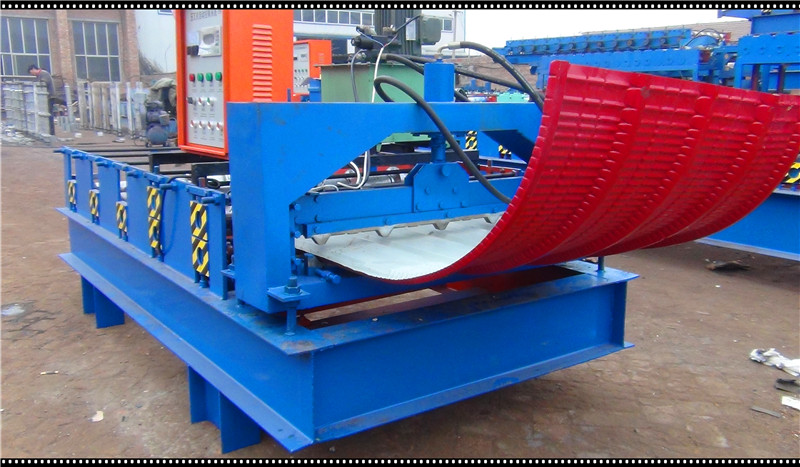

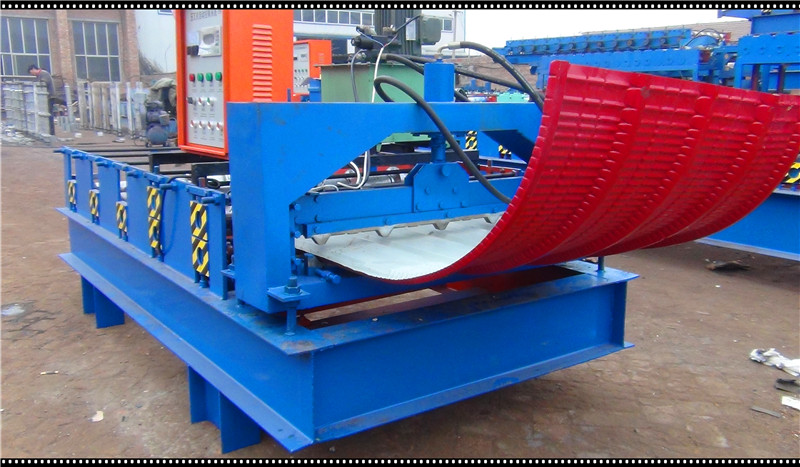

Cangzhou Dixin Curved Roofing Sheet Roll Forming Machine

Basic Info

Model No.: DX curving machine

Product Description

Model NO.: DX Curving Machine Condition: New Usage: Roof Name: Curved Roofing Sheet Roll Forming Machine Control System: PLC(Imported Brand) Material of Rollers: Forged C45 Steel Feature: High Safety Level Cutting Blade Material: Cr 12 High Grade Steel Trademark: DIXIN Origin: Botou City, Hebei Province Certification: SGS, CE, ISO Customized: Customized Transmission Method: Hydraulic Pressure Color: Blue Raw Material: Color Steel Sheet Shaft Material: 45# High Grade Steel Thickness: 0.3-0.7mm Main Frame: 250mm H-Beam Specification: CE ISO BV HS Code: 84552210 Cangzhou Dixin curved roofing sheet roll Forming Machine

Technical Parameters of curved roofing sheet roll forming machine

(1). Material of frame : (high grade) 300mm H shape steel welding

(2).Thickness of middle plate : 20mm

(3). Step of curving roller : 7 steps

(4). Diameter of shaft (solid shaft): 70mm

(5). Material of shaft (solid shaft): (high grade) 45# Steel,quenching and tempering treatment

(6). Material of roller: 45# Steel

(7).Treatment of roller : hard chromize coated

(8). Drive type of roll forming machine : drive by hydraulic motor

(9). Bearing : 6210 (high grade)

(10). Power of main motor : 4KW

(11). Voltage : 380V/50Hz/3phase

(12). Motor power of hydraulic station : 3kw

(13). Oil pump of hydraulic station : gear oil pump (high grade)

(14). Accuracy of curving : +/- 2mm

(15). Appearance size of main forming machine : 2.1m (length)*1.3m (width) *1.2m (height)

(16). Electrically controlled system : entire machine controlled by PLC

(17). PLC: DELTA(TAIWAN)or Mitsubishi

(18). Controlling desktop : Touch screen (high grade)

(19). Electrical parts : DELIXI or CHINT

Delivery:

The machines will be ready within30 days from receipt of down payment as well as approval of sales contract, technical scheme and profile drawing. The shipment will be made within 10 days after the seller receives the balance by T/T.

Terms of payment:

30% of the contract amount as down payment after signed the contract; the balance is to be paid by T/T before shipment. Installation charge is to be paid before installation by T/T.

Cost of installation:

The buyer should pay the installation charges (USD 50 one man one day). to the seller's appointed account by T/T before the seller's technicians go to the buyer's factory. The buyer pays the seller's technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Product warranty:

12 month, and we will provide the technical support for the whole life of the equipment.

Contact us if you need more details on Curving Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forming Machinery、Roll Former. If these products fail to match your need, please contact us and we would like to provide relevant information.

Technical Parameters of curved roofing sheet roll forming machine

| No | Item | Parameter | Note | |

| 1 | Suitable Material | Type | Metal Sheet | Customized Specs Acceptable |

| | Customized Profile | |||

| Thickness | 0.3-0.8mm | |||

| 2 | Product Specs | Cover width | Customized Profile | |

| Length | Any length | | ||

| 3 | Power Specs | Type | 380V/3PH/50HZ | Up to Practical Profile |

| Main Motor | As per design | |||

| Hydraulic | As per design | |||

| 4 | Machine Specs | Transmission | Chain and Sprocket | |

| Structure | Wall Plate | | ||

| Shafter | No.45 steel tempered | | ||

| Rollers | No.45 steel chrome coated | Cr12 or other acceptable | ||

| Cutting Blade | Cr12 quenched | | ||

| Press Mould | Cr12 quenched | | ||

| Punch Mould | Cr12 quenched | | ||

| 5 | Working Capacity | Forming Speed | 0-20m/min | Higher Speed Solution Available |

| Working Speed | Up to Length-set Cutting | |||

| 6 | Manual Decoiler (Optional) | Type | Hydraulic | |

| Max. Capacity | 5 T | | ||

| Suitable coil OD | 1200mm | | ||

| Suitable coil ID | 508/610mm | | ||

| Max Coil width | 1250mm | | ||

| 7 | Forming Stand | 8-30 | Up to Practical Profile | |

| 8 | Forming Shaft Diameter | 55-100mm | Up to Practical Profile | |

| 10 | Control System | DELTA PLC and Inverter | | |

(1). Material of frame : (high grade) 300mm H shape steel welding

(2).Thickness of middle plate : 20mm

(3). Step of curving roller : 7 steps

(4). Diameter of shaft (solid shaft): 70mm

(5). Material of shaft (solid shaft): (high grade) 45# Steel,quenching and tempering treatment

(6). Material of roller: 45# Steel

(7).Treatment of roller : hard chromize coated

(8). Drive type of roll forming machine : drive by hydraulic motor

(9). Bearing : 6210 (high grade)

(10). Power of main motor : 4KW

(11). Voltage : 380V/50Hz/3phase

(12). Motor power of hydraulic station : 3kw

(13). Oil pump of hydraulic station : gear oil pump (high grade)

(14). Accuracy of curving : +/- 2mm

(15). Appearance size of main forming machine : 2.1m (length)*1.3m (width) *1.2m (height)

(16). Electrically controlled system : entire machine controlled by PLC

(17). PLC: DELTA(TAIWAN)or Mitsubishi

(18). Controlling desktop : Touch screen (high grade)

(19). Electrical parts : DELIXI or CHINT

Delivery:

The machines will be ready within30 days from receipt of down payment as well as approval of sales contract, technical scheme and profile drawing. The shipment will be made within 10 days after the seller receives the balance by T/T.

Terms of payment:

30% of the contract amount as down payment after signed the contract; the balance is to be paid by T/T before shipment. Installation charge is to be paid before installation by T/T.

Cost of installation:

The buyer should pay the installation charges (USD 50 one man one day). to the seller's appointed account by T/T before the seller's technicians go to the buyer's factory. The buyer pays the seller's technicians travel cost outside China, including round air tickets fee, accommodation and food, provide transportation from living hotel to the work place, necessary communication, and insurance, etc.

Product warranty:

12 month, and we will provide the technical support for the whole life of the equipment.

Contact us if you need more details on Curving Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forming Machinery、Roll Former. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Roof Curving Machine

Premium Related Products

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine