Best building zinc roofing sheet making machine

Basic Info

Model No.: 910 colored steel machine

Product Description

| 1. The Product Description of Zinc roofing sheet making machine |

| Suitable Material | Q235 or equivalent |

| Material Thickness | 0.3-0.8 mm |

| Material Width | 914, 1000, 1200, 1220 or 1250, as per the drawing |

| Dimension | About 6.8*1.6*1.25m(L*W*H) , as per the drawing |

| Working Space | About 16.8*3.1m(L*W) , as per the drawing |

| Length of the Sheet | You can set the length according to your need. It is controlled by PLC which can ensure the accuracy of ±1mm. |

| Cutting | Automatically stop and cutting when it comes to the set length. |

| Roller Material | High grade 45# steel. Hard chrome plating, 0.05mm. |

| Main Frame | 400# steel. More stable and no shaking. |

| Middle Plate | 16mm. We use thicker plates to ensure stability of our products. |

| Forming Steps | 11-16, according to the drawing. |

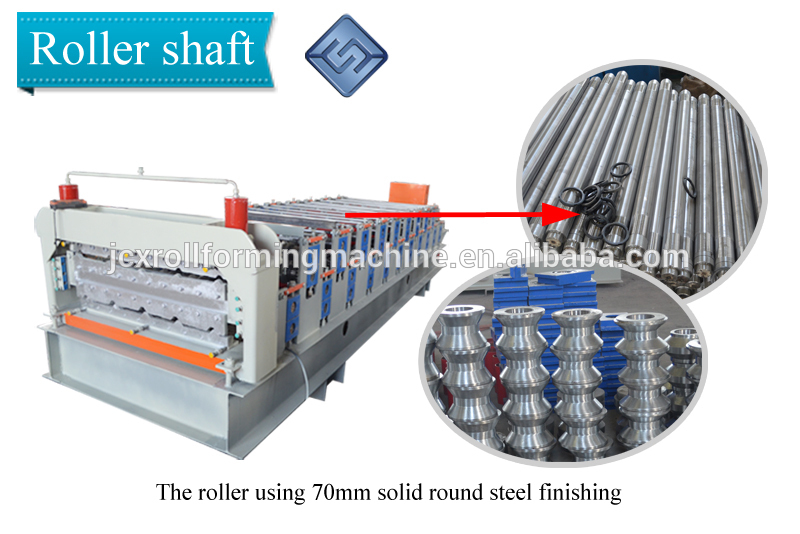

| Shaft Material | Φ70 mm, high grade 45# steel. |

| Treating process: tempering- finish turning, high rigidity, hard to deform. | |

| Cutting Blade Material | Cr12, hardness HRC60-62. |

| Treating process: heat treatment- plane abrasion- wire electrode cutting. |

| Suitable Power | 380V, 50 Hz, 3 phase or according to your need. |

| Screen | 5.7 inch touch screen, easy to operate. |

| PLC | Delta DVP 14ES |

| well-adapted to various conditions, such as moisture, electromagnetic disturbance. | |

| Frequency Converter | DeltaVFD-M. It has the advantage of slowing down before cutting, to ensure the length accuracy (±1mm, far better than industrial standard ±3mm). |

| Length Measurement Device | Omron, made in Japan. |

| It features with high accuracy and stability. |

our certafication

our accessory part

our accessory part

we are together with customer

we are together with customer

machine pictures

machine pictures

Contact us if you need more details on Roofing Sheet Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Zinc Roofing Sheet Making Machine、Best Building Zinc Roofing Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Roofing Sheet Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Zinc Roofing Sheet Making Machine、Best Building Zinc Roofing Sheet Making Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Other Forming Machine

Premium Related Products