steel construction machinery Aluminium GLazed Roofing Tile Cold Roll Forming Machine Roll Former

Basic Info

Model No.: 800

Product Description

1, steel construction machinery Aluminium GLazed Roofing Tile Cold Roll Forming Machine Roll Former Main parts of Roll Forming Machine

1, steel construction machinery Aluminium GLazed Roofing Tile Cold Roll Forming Machine Roll Former Main parts of Roll Forming Machine | 1 uncoiler and its base |

| 2 coil sheet guiding equipment |

| 3 roll forming system |

| 4 hydraulic pressing equipment |

| 5 post cutting equipment |

| 6 hydraulic station |

| 7 controlling system |

| 8 supporter table |

| 1 automatic hydraulic glazed tile making machine |

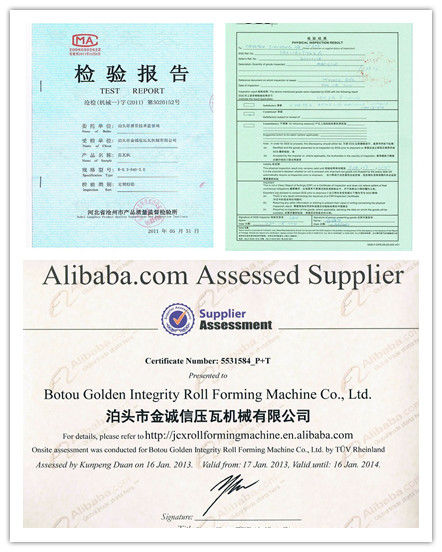

| 2 ISO&CE |

| 3 no scratch smooth |

| 4 good quality |

| 5 durable Tile Forming Machine |

| 1. material spec: colored steel sheet, galvanized steel sheet, aluminium sheet |

| 2. thickness of coil sheet: 0.3-0.8mm |

| 3. roller material: high grade NO.45 forged steel, with hard chrome plating on the surface of roller with thickness 0.05mm |

| 4. shaft material: high grade NO.45 carbon wrought steel |

| 5. cutting blade: Cr12 mould steel with quenched treatment |

| 6. diameter of shaft: 70-90mm |

| 7. thickness of medium plate: 14-20mm |

| 8. main frame: 300H/U steel |

| 9. number of forming steps: 15 rows |

| 10. productivity: 1-3m/min |

| 11. main motor power: 5kw |

| 12. hydraulic station power: 4kw |

| 13. hydraulic pressure: 10-12MPa |

| 14. controlling system: PLC computer control |

| 15. Voltage: 380V 3Phase 60Hz or at buyer’s requirement |

| 1 feed lubricant |

| 2 power lines properly connected |

| 3 change the gear oil and hydraulic oil |

| 1 20-ft or 40-ft container depends on rows of production line |

| 2 Most of the machine is naked |

| 3 Rollers,shafts and PLC control system will be packed in waterproof package |

| 4 Some other measurements will be taken to protect machines. For example..machines will be fixed with containers with wire rope. |

| 1 Roll forming machines will be loaded from botou to tianjin port in a container |

| 2 Machines will be shipping from tianjin port to your destination port |

| 1 one year warranty and lifelong technical support (During warranty you will have to pay for part of fee including visa,tickets and othes) |

| 2 on-site training. Training period willbe for no more than one week with the customer paying for the visa return ticket, food, accommodations and a daily wage of USD 80. |

| 1 Contact us and find your interested panel profile of toll Forming Machine. 2 Design and make a quotation about your machines. 3 Make chage and order confirmation 4 Complete contract and proforma invoice 5 Pay for 30% deposit in advance and balance before loading. 6 Produce the machine 7 Inspect machine on-site or by video and pay for balance 8 Usually load ship by tianjin port 9 Send you related documents. 10 On-site overseas training and fixing available for fee. |

Contact us if you need more details on Steel Construction Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminium Glazed Roofing Tile、Cold Roll Forming Machine Roll Former. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Steel Construction Machinery. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Aluminium Glazed Roofing Tile、Cold Roll Forming Machine Roll Former. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Other Forming Machine

Premium Related Products