used guardrail for sale

Basic Info

Model No.: 310 highway guardril machine

Product Description

Highway Guardrail Roll Forming Machine 1. Brief Introduction

This roll Forming Machine is for steel sheet cold-form industries. It can form the

highway guard rail sheets according to customer’s requirement continuously, and then

automatically cut to length. The equipment adopts PLC control, AC frequency and

adjusting the speed technology, and it realizes the continuous automatically

production. Therefore it is really a new type of energy-saving and high-effective

equipment for guard rails. And it has many advantages, just like high forming speed,

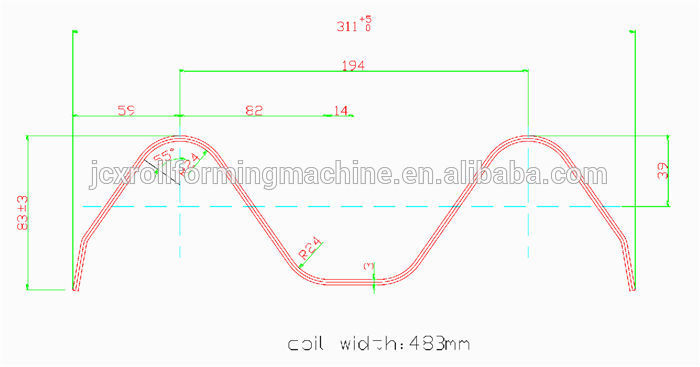

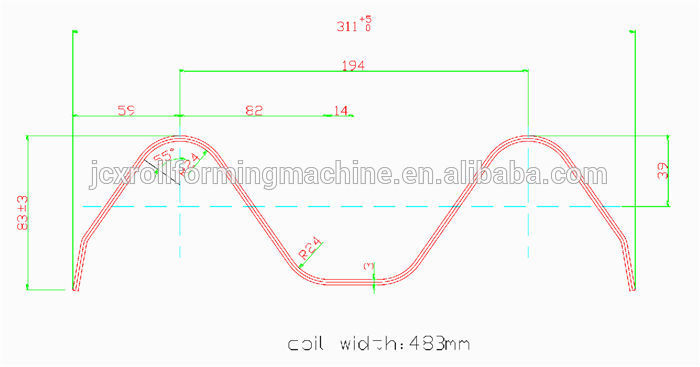

low noise, stable transmission, easy operation, good appearance and so on. 2. Technical Parameters 1)Coil Width:483mm, Q345 2)Forming speed 15 m/min (not including cutting time)

3)Roller Stations:16 stations

4)Material of Roller:45# steel finish machining, plated hard chromium surface

5)Material of Main Shaft:45# steel finishing machining and then slack quench processed, 100MM diameter, 45#steel forged

6)Driven Motor Power:37 KW AC frequency controlled

7)Hydraulic Station Power:7.5 KW

8)Hydraulic Station Pressure:20 Mpa

9)Electrical Control System:PLC, Touch Screen , Inverter , Encoder, etc International brands

10)Dimension (L*W*H):9000mm*1350mm*1200mm

11)Material of Cutter:GCr12

12)Driving Mode:Gear Box

13)Material Thickness:2.5-3.0mm

14)Power Supply:440 V,50HZ, 3 PHASES

15)Cutting accuracy:±2 mm

3. Components and Function Decoiler:

This decoiler is passive type, which could load coil by expanding the bolts fix at coil inner diameter. It’s easy to be operated as an economical solution

Guiding Device:

Adopt guiding bar and sliding block to control the width and position of the steel sheet. The

coil is guided in the correct position and passed to the roll forming system. Can adjust the guiding bar with loosing the fixing bolts to feed sheet in right position. It’s fixed structure

to make sure can not move easily. Leveling Device:

This device is to make the steel strip go into the roll forming system flatly and straightly. It

consist of seven small leveling rollers (3 pieces up and 4 pieces down), which can

achieve good leveling quality.

Punching Device:

The punching dies adopt Cr12 with quenched treatment. The holes made by these punching

moulds are easy to be installed together. Because the holes are finished with high precision. The device has advanced techniques, quick action, long life and low noise. You could control it easily.

Roll Forming System:

A. Machine frame adopts welding structure with shot blasting and painting treatment B. All rollers material adopt high quality GCR15 steel with quenching treatment and tempering treatment, and the hardness reaches to HRC58-62. All rollers are treated by full CNC machines to make sure the rollers with good rigidity and precision, and form perfect sheets as per design.

C. All rolling shafts are made by high quality No.45 steel with quenching and tempering treatment, so the shafts with good rigidity which could use for long tern without

deformation.

D. Rolling shaft supporting structure type is steel wall and welded with the basement together to have rigidity.

E. Cycloidal pin gear speed reducer motor driven, the back/forward roller driven by chain, part of upper/lower rollers driven by gear. Cutting Device:

A. Adopts post cutting, the cutting blade material is Cr12 with quenched treatment.

B. Adopts welded frame for good rigidity.

C. The cutting action is driven by the power from hydraulic station which guarantees the

precision of cutting and low noisy, long life.

Hydraulic Station:

A. Adopts separated hydraulic station for punching device and cutting device.

B. Supply the initial power to the puncher and cuter through a closed oil tank.

C. All valves, motors, pumps and pipes are from high quality Chinese famous brand

suppliers.

PLC Control System:

A. Adopts PLC control and frequency adjust speed, length measurement encoder calculation technology, realize the automatic production.

B. Pressing button Operation, adopt high quality components, such as Mitsubishi PLC,transducer and touching screen, Omron mini-relays, Schneider AC contactor,switches, and so on.

C. The system uses modular structure with convenient, reasonable wiring arrangement.

Finished Panel Supporter:

It can be used to hold finished panels. We supply 2 pieces with length of 2000mm.

Normally 2 pieces supporters together can hold 7000mm panels. 4.Working Flow

Decoiling the sheet ---Sheet guiding ---Leveling--- Punching---Roll forming ---Measuring length ---Cutting the panel ---Panels to the supporter 5.Components of the machine

Decoiler 1 set Guiding device 1 set

Leveling device 1 set

Punching device 1 set

Roll forming system 1 set Guiding device 1 set

Finish panel supporter 2 sets PLC control system 1 set

Hydraulic station 1 set 6.Picture Show

7.Loading Sence

7.Loading Sence  PAYMENT 30% paid by TT in advance and the balance paid by TT before shipping OUR ADVANTAGE 1)---High Quality 2)---Reliable 3)---Durable 4)---Reasonable Price 5)---Good after Service 6)---Passed ISO9001:2008 certification 7)---Passed CE certification AFTER SALE SERVICE - The seller take responsibility to installation and commissioning of the equipment and free training. After machine arrive the destination, by the request of the buyer , the seller will provide 1 technical engineer to guide installation and training , and the buyer should give the technical person with full cooperated. - Installation period: about 5 days after the complete preparation by the buyer such as the foundation and all necessary accessories. - Training time: 5 days. - Before departure of the engineers from seller, the buyer should pay for installation and commissioning fee 100$/day to the point account of the seller. The two-way ticket,visa, food, hotel , the translator and insurance are all should provide by buyer with full responsibility. -The seller supply technical data (including forming mould drawing, electrical elements drawing and equipment drawing etc.) Welcome to contact and visit us, waiting for your cooperation sincerely. Mob:+86 18732755439 Skype:Presley.xu Contact us if you need more details on Used Guardrail for Sale. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Used Roll Forming Machine、Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

PAYMENT 30% paid by TT in advance and the balance paid by TT before shipping OUR ADVANTAGE 1)---High Quality 2)---Reliable 3)---Durable 4)---Reasonable Price 5)---Good after Service 6)---Passed ISO9001:2008 certification 7)---Passed CE certification AFTER SALE SERVICE - The seller take responsibility to installation and commissioning of the equipment and free training. After machine arrive the destination, by the request of the buyer , the seller will provide 1 technical engineer to guide installation and training , and the buyer should give the technical person with full cooperated. - Installation period: about 5 days after the complete preparation by the buyer such as the foundation and all necessary accessories. - Training time: 5 days. - Before departure of the engineers from seller, the buyer should pay for installation and commissioning fee 100$/day to the point account of the seller. The two-way ticket,visa, food, hotel , the translator and insurance are all should provide by buyer with full responsibility. -The seller supply technical data (including forming mould drawing, electrical elements drawing and equipment drawing etc.) Welcome to contact and visit us, waiting for your cooperation sincerely. Mob:+86 18732755439 Skype:Presley.xu Contact us if you need more details on Used Guardrail for Sale. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Used Roll Forming Machine、Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

This roll Forming Machine is for steel sheet cold-form industries. It can form the

highway guard rail sheets according to customer’s requirement continuously, and then

automatically cut to length. The equipment adopts PLC control, AC frequency and

adjusting the speed technology, and it realizes the continuous automatically

production. Therefore it is really a new type of energy-saving and high-effective

equipment for guard rails. And it has many advantages, just like high forming speed,

low noise, stable transmission, easy operation, good appearance and so on. 2. Technical Parameters 1)Coil Width:483mm, Q345 2)Forming speed 15 m/min (not including cutting time)

3)Roller Stations:16 stations

4)Material of Roller:45# steel finish machining, plated hard chromium surface

5)Material of Main Shaft:45# steel finishing machining and then slack quench processed, 100MM diameter, 45#steel forged

6)Driven Motor Power:37 KW AC frequency controlled

7)Hydraulic Station Power:7.5 KW

8)Hydraulic Station Pressure:20 Mpa

9)Electrical Control System:PLC, Touch Screen , Inverter , Encoder, etc International brands

10)Dimension (L*W*H):9000mm*1350mm*1200mm

11)Material of Cutter:GCr12

12)Driving Mode:Gear Box

13)Material Thickness:2.5-3.0mm

14)Power Supply:440 V,50HZ, 3 PHASES

15)Cutting accuracy:±2 mm

3. Components and Function Decoiler:

This decoiler is passive type, which could load coil by expanding the bolts fix at coil inner diameter. It’s easy to be operated as an economical solution

Guiding Device:

Adopt guiding bar and sliding block to control the width and position of the steel sheet. The

coil is guided in the correct position and passed to the roll forming system. Can adjust the guiding bar with loosing the fixing bolts to feed sheet in right position. It’s fixed structure

to make sure can not move easily. Leveling Device:

This device is to make the steel strip go into the roll forming system flatly and straightly. It

consist of seven small leveling rollers (3 pieces up and 4 pieces down), which can

achieve good leveling quality.

Punching Device:

The punching dies adopt Cr12 with quenched treatment. The holes made by these punching

moulds are easy to be installed together. Because the holes are finished with high precision. The device has advanced techniques, quick action, long life and low noise. You could control it easily.

Roll Forming System:

A. Machine frame adopts welding structure with shot blasting and painting treatment B. All rollers material adopt high quality GCR15 steel with quenching treatment and tempering treatment, and the hardness reaches to HRC58-62. All rollers are treated by full CNC machines to make sure the rollers with good rigidity and precision, and form perfect sheets as per design.

C. All rolling shafts are made by high quality No.45 steel with quenching and tempering treatment, so the shafts with good rigidity which could use for long tern without

deformation.

D. Rolling shaft supporting structure type is steel wall and welded with the basement together to have rigidity.

E. Cycloidal pin gear speed reducer motor driven, the back/forward roller driven by chain, part of upper/lower rollers driven by gear. Cutting Device:

A. Adopts post cutting, the cutting blade material is Cr12 with quenched treatment.

B. Adopts welded frame for good rigidity.

C. The cutting action is driven by the power from hydraulic station which guarantees the

precision of cutting and low noisy, long life.

Hydraulic Station:

A. Adopts separated hydraulic station for punching device and cutting device.

B. Supply the initial power to the puncher and cuter through a closed oil tank.

C. All valves, motors, pumps and pipes are from high quality Chinese famous brand

suppliers.

PLC Control System:

A. Adopts PLC control and frequency adjust speed, length measurement encoder calculation technology, realize the automatic production.

B. Pressing button Operation, adopt high quality components, such as Mitsubishi PLC,transducer and touching screen, Omron mini-relays, Schneider AC contactor,switches, and so on.

C. The system uses modular structure with convenient, reasonable wiring arrangement.

Finished Panel Supporter:

It can be used to hold finished panels. We supply 2 pieces with length of 2000mm.

Normally 2 pieces supporters together can hold 7000mm panels. 4.Working Flow

Decoiling the sheet ---Sheet guiding ---Leveling--- Punching---Roll forming ---Measuring length ---Cutting the panel ---Panels to the supporter 5.Components of the machine

Decoiler 1 set Guiding device 1 set

Leveling device 1 set

Punching device 1 set

Roll forming system 1 set Guiding device 1 set

Finish panel supporter 2 sets PLC control system 1 set

Hydraulic station 1 set 6.Picture Show

7.Loading Sence

7.Loading Sence  PAYMENT 30% paid by TT in advance and the balance paid by TT before shipping OUR ADVANTAGE 1)---High Quality 2)---Reliable 3)---Durable 4)---Reasonable Price 5)---Good after Service 6)---Passed ISO9001:2008 certification 7)---Passed CE certification AFTER SALE SERVICE - The seller take responsibility to installation and commissioning of the equipment and free training. After machine arrive the destination, by the request of the buyer , the seller will provide 1 technical engineer to guide installation and training , and the buyer should give the technical person with full cooperated. - Installation period: about 5 days after the complete preparation by the buyer such as the foundation and all necessary accessories. - Training time: 5 days. - Before departure of the engineers from seller, the buyer should pay for installation and commissioning fee 100$/day to the point account of the seller. The two-way ticket,visa, food, hotel , the translator and insurance are all should provide by buyer with full responsibility. -The seller supply technical data (including forming mould drawing, electrical elements drawing and equipment drawing etc.) Welcome to contact and visit us, waiting for your cooperation sincerely. Mob:+86 18732755439 Skype:Presley.xu Contact us if you need more details on Used Guardrail for Sale. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Used Roll Forming Machine、Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

PAYMENT 30% paid by TT in advance and the balance paid by TT before shipping OUR ADVANTAGE 1)---High Quality 2)---Reliable 3)---Durable 4)---Reasonable Price 5)---Good after Service 6)---Passed ISO9001:2008 certification 7)---Passed CE certification AFTER SALE SERVICE - The seller take responsibility to installation and commissioning of the equipment and free training. After machine arrive the destination, by the request of the buyer , the seller will provide 1 technical engineer to guide installation and training , and the buyer should give the technical person with full cooperated. - Installation period: about 5 days after the complete preparation by the buyer such as the foundation and all necessary accessories. - Training time: 5 days. - Before departure of the engineers from seller, the buyer should pay for installation and commissioning fee 100$/day to the point account of the seller. The two-way ticket,visa, food, hotel , the translator and insurance are all should provide by buyer with full responsibility. -The seller supply technical data (including forming mould drawing, electrical elements drawing and equipment drawing etc.) Welcome to contact and visit us, waiting for your cooperation sincerely. Mob:+86 18732755439 Skype:Presley.xu Contact us if you need more details on Used Guardrail for Sale. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Used Roll Forming Machine、Cold Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Highway Guardrail

Premium Related Products

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine