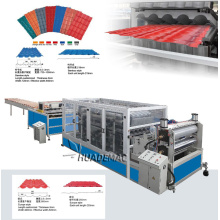

Slant Arc Glazed Tile Rolling Forming Machine/Step Tile Roofing Sheet Rolling Former Line JCX1000

Basic Info

Model No.: JCX--1100 glazed tile

Product Description

Specifications Welcome to review our Roll Forming Machine

we are manufacture

save space

excellent quality

complete service

Welcome to view JCX 1100 glazed tile roll Forming Machine according to customers requirements ,costom roll forming machine panel picture

Roll Forming Machine parameter

Roll Forming Machine parameter

we are manufacture

save space

excellent quality

complete service

Welcome to view JCX 1100 glazed tile roll Forming Machine according to customers requirements ,costom roll forming machine panel picture

Roll Forming Machine parameter

Roll Forming Machine parameter | Name | Value |

| Brand | JCX |

| Model | JCX28-220-1100 |

| Production Capacity | 3-5M/MIN |

| Automatic Grade | FULLY AUTOMATIC |

| Voltage | 220V/380/410/440V |

| Power | 4KW |

| Place of Origin | Botou,China |

| Year | 2013 |

| Certification | N/A,TUV |

| Dimension(L*W*H) | 6.5x1.55x1.51m |

| Weight | 5ton |

| Warranty | One year |

No. |

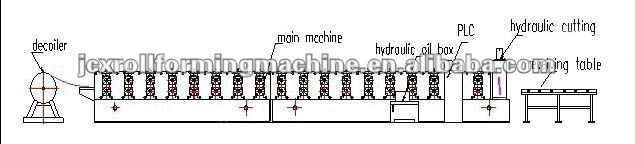

Processes: Manual decoiler—Roll forming machine—PLC system—Hydraulic system-Post cut—Stacking Components of line: Processes: Manual decoiler—Roll forming machine—PLC system—Hydraulic system-Post cut—Stacking Components of line:

<1>. Manual un-coiler

| ||||||||||||||||||||||||||||||||||||||

Stacker : Optional (1). manual

Stacker : Optional (1). manual  (2) Auto

(2) Auto

EXELLENT QUALITY AND COMPETITIVE PRICE! CHOOSE US , CHOOSE THE BEST! Thank you for your time! Contact us if you need more details on Step Tile Roofing Sheet Rolling Former Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about

EXELLENT QUALITY AND COMPETITIVE PRICE! CHOOSE US , CHOOSE THE BEST! Thank you for your time! Contact us if you need more details on Step Tile Roofing Sheet Rolling Former Line. We are ready to answer your questions on packaging, logistics, certification or any other aspects about