JCX hot sale automatic deck forming machine made in china

Basic Info

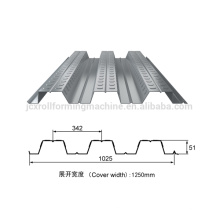

Model No.: 51-240-720

Product Description

JCX hot sale automatic deck Forming Machine made in china Product Description 1.the technical parameters of Floor decking sheet Roll Forming Machine

2.process flow  3.Some photos for your reference

3.Some photos for your reference

4.Components of line:

4.Components of line:

4. summary of the structure (1) Common uncoiler Functional and structural characteristics : It is used to support the Steel Coil and uncoil it in a turnable way. The steel coil is uncoiled by hand. The uncoiler can bear 5t. It is suitable to process the coiled steel with the inside diameter 508mm .  (2) Feeding the material into the platform Functional and structural characteristics :put the raw material(steel srip) on the plat to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

(2) Feeding the material into the platform Functional and structural characteristics :put the raw material(steel srip) on the plat to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.  (3) Molding core Functional and structural characteristics :In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,chain transmission, roller surfaces polishing, hard plating, heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stampted. Rolling galvanizational thickness:0.01 mm Rolling material: Forging Steel 45# Material of the mold: Cr40. and the mold is heat-treated. (4) Shearing mechanism It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Match equipment: It contains one set of cutting tools, one hydraulic tank and one cutter machine. Material of the cutting blade: Gcr12 (5) Hydraulic system It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job. Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves. Power of the oil pump: 3kw; Hydraulic oil: 40#;

(3) Molding core Functional and structural characteristics :In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,chain transmission, roller surfaces polishing, hard plating, heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stampted. Rolling galvanizational thickness:0.01 mm Rolling material: Forging Steel 45# Material of the mold: Cr40. and the mold is heat-treated. (4) Shearing mechanism It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Match equipment: It contains one set of cutting tools, one hydraulic tank and one cutter machine. Material of the cutting blade: Gcr12 (5) Hydraulic system It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job. Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves. Power of the oil pump: 3kw; Hydraulic oil: 40#;  (6) Computer control cabinet: It adopts Panasonic to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

(6) Computer control cabinet: It adopts Panasonic to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.  (7) Counter : One counter gauges length, pulses, and decides length

(7) Counter : One counter gauges length, pulses, and decides length  (8) Molded pieces receiving table It adopts welded steel and supported roller to transmit the products. There are two frames with the length of 3m/one.

(8) Molded pieces receiving table It adopts welded steel and supported roller to transmit the products. There are two frames with the length of 3m/one.  Packaging & Shipping Payment:30% T/T in advance, balance 70% after inspection confirmation before shipment. Delivery: within 40 working days after receipt of deposit.

Packaging & Shipping Payment:30% T/T in advance, balance 70% after inspection confirmation before shipment. Delivery: within 40 working days after receipt of deposit.  Contact us if you need more details on Metal Forming. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Deck Fomring Machines、Portable Metal Roofing Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Metal Forming. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Deck Fomring Machines、Portable Metal Roofing Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

| Floor decking sheet roll forming machine Description | Introduction |

| Working efficiency | 8-12m/min |

| Thickness of Material | 0.3-1.5mm(can be changed according to customers need) |

| Width of material | According to customers need |

| Control system | PLC(The brand can be choose) |

| Uncoiler system | 5Ton Manual Operation(1250mm width) |

| Forming by rolling | 24 rows(According to the machine design) |

| Roller material | GCR15 Aluminium processing after quenchin HRC58-62°C,Chrome plated |

| Shaft and the diameter of axle | 45#Aluminium-processing ,diameter of axle=100mm |

| Main part power | 2*11kw |

| Hydraulic motor power | 5.5kw |

| Hydraulic pressure | 12Mpa |

| Scissor material | Cr12Mov, herd steel HRC 58-62°C |

| length tolerance | ±1.5mm |

| voltage | 380V, 50HZ,3 phase(adjustable by customer needs) |

| Frame form | Middle plate |

| Driving Method | Chain |

| Color | Yellow and blue(adjustable) |

| Size | length*Width*Height - 6.8*0.8*1.2m |

| weight | about 8.5T |

| Package | Nude package in 1*40GP container |

| Delivery date | 40 working days |

| Payment Method | 30% T/T in advance and balance 70% after inspection confirmation before shipment. |

3.Some photos for your reference

3.Some photos for your reference

4.Components of line:

4.Components of line: No. | Name | Unit | Qty |

1 | Man-made uncoiler | set | 1 |

2 | Main machine for roll forming | set | 1 |

3 | Control system | set | 1 |

4 | Hydraulic system | set | 1 |

5 | Mold pressing machine | set | 1 |

6 | Blade | set | 1 |

7 | Receiving table | set | 2 |

(2) Feeding the material into the platform Functional and structural characteristics :put the raw material(steel srip) on the plat to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

(2) Feeding the material into the platform Functional and structural characteristics :put the raw material(steel srip) on the plat to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.  (3) Molding core Functional and structural characteristics :In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,chain transmission, roller surfaces polishing, hard plating, heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stampted. Rolling galvanizational thickness:0.01 mm Rolling material: Forging Steel 45# Material of the mold: Cr40. and the mold is heat-treated. (4) Shearing mechanism It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Match equipment: It contains one set of cutting tools, one hydraulic tank and one cutter machine. Material of the cutting blade: Gcr12 (5) Hydraulic system It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job. Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves. Power of the oil pump: 3kw; Hydraulic oil: 40#;

(3) Molding core Functional and structural characteristics :In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,chain transmission, roller surfaces polishing, hard plating, heat treatment and galvanizational treatment . The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stampted. Rolling galvanizational thickness:0.01 mm Rolling material: Forging Steel 45# Material of the mold: Cr40. and the mold is heat-treated. (4) Shearing mechanism It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Match equipment: It contains one set of cutting tools, one hydraulic tank and one cutter machine. Material of the cutting blade: Gcr12 (5) Hydraulic system It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank, the pump drive the cutter machine to begin the cutting job. Match equipment: The system includes a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes.and two sets of electromagnetism valves. Power of the oil pump: 3kw; Hydraulic oil: 40#;  (6) Computer control cabinet: It adopts Panasonic to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.

(6) Computer control cabinet: It adopts Panasonic to control. The target piece’s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use.  (7) Counter : One counter gauges length, pulses, and decides length

(7) Counter : One counter gauges length, pulses, and decides length  (8) Molded pieces receiving table It adopts welded steel and supported roller to transmit the products. There are two frames with the length of 3m/one.

(8) Molded pieces receiving table It adopts welded steel and supported roller to transmit the products. There are two frames with the length of 3m/one.  Packaging & Shipping Payment:30% T/T in advance, balance 70% after inspection confirmation before shipment. Delivery: within 40 working days after receipt of deposit.

Packaging & Shipping Payment:30% T/T in advance, balance 70% after inspection confirmation before shipment. Delivery: within 40 working days after receipt of deposit.  Contact us if you need more details on Metal Forming. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Deck Fomring Machines、Portable Metal Roofing Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Metal Forming. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Deck Fomring Machines、Portable Metal Roofing Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Floor Deck Roll Forming Machine Series

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine