Alibaba 1100/1016 Double Layers Roll Forming Machine Machinery

Basic Info

Model No.: JCX

Product Description

Condition | New |

Type | |

Tile Type | Colored Glazed Steel/colored steel |

Use | Roof |

Production Capacity | 9-12m/min |

Place of Origin | Hebei, China (Mainland) |

Brand Name | JCX |

Power(W) | 5kw |

Voltage | 380/220/440 |

Dimension(L*W*H) | 7.5mX1.6mX1.7m |

Weight | 5t |

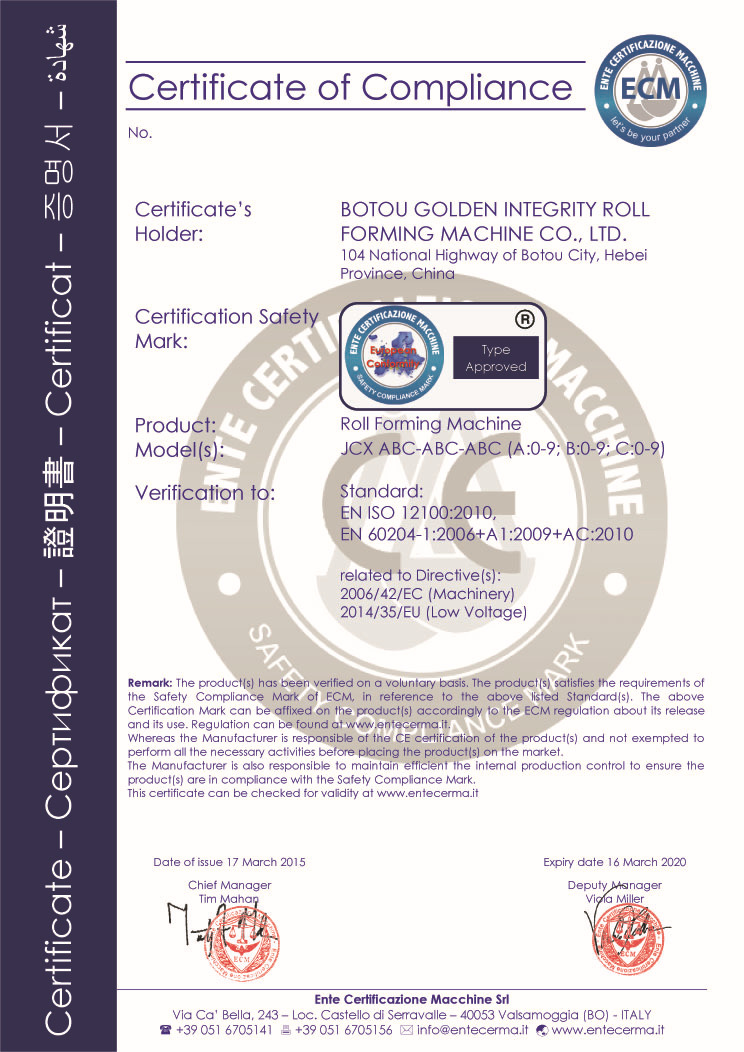

Certification: | CE&BV/ISO9001 |

Warranty | 1year |

Model Number | JCX |

color | Can produce as u like |

Size | Can produce as u like |

OEM | Available |

ODM | Available |

3. Profile:

3. Profile:  4. Detailed Specification

4. Detailed Specification No. | Item | Description |

1 | Suitable material | Color steel sheet ,galvanized steel sheet, Aluminium sheet |

2 | Working speed | 8-15m/min |

3 | Main motor power | 4kw with cycloidal reducer |

4 | Hydraulic station power | 4kw |

5 | Electrical control system | PLC control system with famous brand |

6 | Thickness of material | 0.25mm~0.8mm |

7 | Shaft diameter | 70mm |

8 | Roller station | 18stations |

9 | Material expand axis | 1200mm,1220mm,1250mm |

10 | Dimension | 8500x1500x1500mm |

11 | Driving mode | Chain |

12 | Electric tension | 380V 3phase 50HZ or as the customer's requirements |

13 | Material of roller | High grade 45# forged steel plated with hard chrome plating |

14 | Material of cutting | Cr12 mould steel with quenched treatment |

15 | Working time | Can be 24 hours |

16 | Workers | 1-2 only |

NO | Name | Unit | Qty |

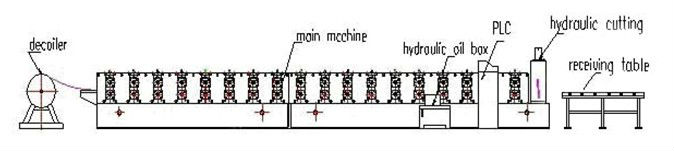

1 | Automatic/Man-made decoiler | set | 1 |

2 | Main machine for roll forming | set | 1 |

3 | Control system | set | 1 |

4 | Hydraulic system | set | 1 |

(2) Main Machine -Roll-Forming M/C:

Steps:10-11steps Roller Material: 45# steel Voltage: 3phase/380V/50-60Hz. line speed:8-10m/min; Rolling chromium thickness:0.05 mm

Cutting Mechanism It adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut, Post cut cutting length tolerance: ±2mm Cutting tool material: GCr12 with quenched treatment 60-62°C

Cutting Mechanism It adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut, Post cut cutting length tolerance: ±2mm Cutting tool material: GCr12 with quenched treatment 60-62°C  (3)Computer control cabinet : It adopts PLC to control. The target piece length is adjustable and digit of it can be adjusted Computed mode has two modes: automatic and manual one.

(3)Computer control cabinet : It adopts PLC to control. The target piece length is adjustable and digit of it can be adjusted Computed mode has two modes: automatic and manual one.  (4) Hydraulic System It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves. Power of the oil pump: 3kw Hydraulic oil :40#

(4) Hydraulic System It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job. Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves. Power of the oil pump: 3kw Hydraulic oil :40# 6. Advantages 1. We are a manufacturer, specialied in all kinds of roll forming machine. 2. 15 years of experience for manufacturing and exportation. 3. Customers Design, Size, Color and Logo are accepted. 4. Elegant apparene good quality, compotitive price, 5. Simple control, good after-service and Prompt Delivery. 6. Main markets: Middle East, Europe, North America, Africa and Southeast Asia. Packaging & Shipping Packaging and Shipping 1. Delivery time: 30 Days after the receipt of advanced payment 2. Payment terms:30 %Advance Payment ;70% Payment before shipment, after examination of the machines 3. Packing: The roll Forming Machine main body is naked; The control box, hydraulic station and other spare parts are packed with plywood box. 4. Port of loading: XinGang, Tianjin , China 5. Warranty: One year warranty for service

6. Advantages 1. We are a manufacturer, specialied in all kinds of roll forming machine. 2. 15 years of experience for manufacturing and exportation. 3. Customers Design, Size, Color and Logo are accepted. 4. Elegant apparene good quality, compotitive price, 5. Simple control, good after-service and Prompt Delivery. 6. Main markets: Middle East, Europe, North America, Africa and Southeast Asia. Packaging & Shipping Packaging and Shipping 1. Delivery time: 30 Days after the receipt of advanced payment 2. Payment terms:30 %Advance Payment ;70% Payment before shipment, after examination of the machines 3. Packing: The roll Forming Machine main body is naked; The control box, hydraulic station and other spare parts are packed with plywood box. 4. Port of loading: XinGang, Tianjin , China 5. Warranty: One year warranty for service

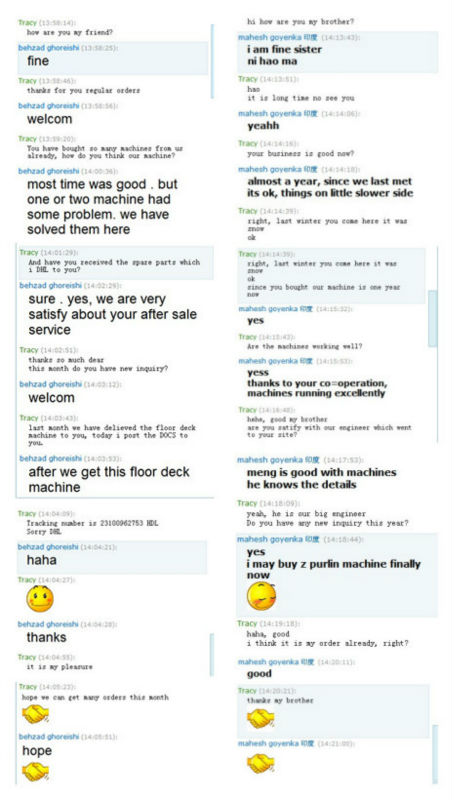

Our Services Our Servicesand Guarantee 1. We provide lifelong service during guarantee time and after guarantee time. 2. Except the wearing parts, 12 months guarantee for machine and 6 months guarantee for electric appliance after shipment. 3. During guarantee time, if any parts go broken and not artificial damage, we will send you new ones for free in the warranty period; if the parts were broken caused by the mishandling by the buyers, engineers available to service machinery overseas if the buyers require. But the extal expenses in cluding the charge of visa, the air ticket, the accommodation and trafficfee will be for the buyer’s account.

Our Services Our Servicesand Guarantee 1. We provide lifelong service during guarantee time and after guarantee time. 2. Except the wearing parts, 12 months guarantee for machine and 6 months guarantee for electric appliance after shipment. 3. During guarantee time, if any parts go broken and not artificial damage, we will send you new ones for free in the warranty period; if the parts were broken caused by the mishandling by the buyers, engineers available to service machinery overseas if the buyers require. But the extal expenses in cluding the charge of visa, the air ticket, the accommodation and trafficfee will be for the buyer’s account.  Company Information We have been established in 1995 as a professional manufacturer of ROLL FORMING MALCHINE. We use AUTO CAD design software. With more than 10 years of experience and strict quality control, our products meet International Standard and enjoy great popularity all over the world. Now We are the leading manufacturer of roll forming machine in China. We manufacture various kinds of roll forming machines for producing such products as Roof Tile, Wall Panel, Roofing Corrugated Sheet, Floor Deck, C & Z Purling, Highway Guardrail, Sandwich Panel, Container Board, Car Panel, Roll Shutter Door, Downspout, Decorated gusset, Steel Pipe, etc. Botou Golden Intergrity Roll Forming Machine Co., Ltd Nancang Street, Botou City,Hebei Province,China ZIP:062150 Tel: 86-317-8185399 Fax:86-317-8193636 TradeManager: cn1046671675 Mobile:008618915127311(whats app)

Company Information We have been established in 1995 as a professional manufacturer of ROLL FORMING MALCHINE. We use AUTO CAD design software. With more than 10 years of experience and strict quality control, our products meet International Standard and enjoy great popularity all over the world. Now We are the leading manufacturer of roll forming machine in China. We manufacture various kinds of roll forming machines for producing such products as Roof Tile, Wall Panel, Roofing Corrugated Sheet, Floor Deck, C & Z Purling, Highway Guardrail, Sandwich Panel, Container Board, Car Panel, Roll Shutter Door, Downspout, Decorated gusset, Steel Pipe, etc. Botou Golden Intergrity Roll Forming Machine Co., Ltd Nancang Street, Botou City,Hebei Province,China ZIP:062150 Tel: 86-317-8185399 Fax:86-317-8193636 TradeManager: cn1046671675 Mobile:008618915127311(whats app)  FAQ Payment terms:T/T, L/C, Cash, EXW,C&F,CIF are available Delivery: usually within 30 working days. Warranty: 12 months since the machine left seller’s factory.We provide lifelong service during guarantee time and after guarantee time. Except the wearing parts, 12 months guarantee for machine and 6 months guarantee for electric appliance after shipment. Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to order from us. 5. Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details: (a) For the C,Z,W Profile and roof/wall panel roll forming machine: the material thickness range, width range and the profile drawing are required (how many roll forming stations required are depended on the profile drawing); (b) For the slitting line and cut-to-length: the material type (HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers (only for slitting line), steel plate required cutting length (only for cut-to-length line); (C)For the HVAC machine and the stainless steel pipe machine: the wall thickness range and the diameter range of the pipe; Pls also provide us with your special requirements for the machine, for example, you want the machine to be a full-automatic one or semi-automatic one in order to save your procurement budget. 6. Q: How can we be assured that you will deliver us quality machine with spare parts? A: We usually require our customers to send the technical people to our factory for checking the quality of the machine before shipping. Considering that the buyer usually is not very familiar with the machine assembling and debugging, so we send the technicians to the buyer’s factory for the installation of the machine provided that the Price Term was conclude on ALL IN basis. In addition, we provide all of our customers with the after sales-service; it’s free of charge during the warranty period. 7. Q: Do you have after-sales service? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. During guarantee time, if any parts go broken and not artificial damage, we will send you new ones for free in the warranty period; if the parts were broken caused by the mishandling by the buyers, engineers available to service machinery overseas if the buyers require. But the extal expenses in cluding the charge of visa, the air ticket, the accommodation and traffic fee,etc, will be for the buyer’s account. 8. Q: How do your machines compare with other big companies in this market? A: We are willing to update our products with the latest technology and improve our machines accordingly. 9. Q: How does your factory do regarding quality control? A: Quality is priority. JCX People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 10. Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. JCX is ALIBAB’s Gold supplier with CE assessment. If you check with ALIBABA, you will see that we have never got any complaint from our customers. Buyer Feedback

FAQ Payment terms:T/T, L/C, Cash, EXW,C&F,CIF are available Delivery: usually within 30 working days. Warranty: 12 months since the machine left seller’s factory.We provide lifelong service during guarantee time and after guarantee time. Except the wearing parts, 12 months guarantee for machine and 6 months guarantee for electric appliance after shipment. Q: Can you make the machine according to my design or prototype? A: Yes. We have an experienced team for working out the most suitable design and production plan for the machine that you are going to order from us. 5. Q: What do you need to know so that I can have a machine plan from you for our technical people reference? A: Well, as the basic needed information for designing a machine plan, pls see below details: (a) For the C,Z,W Profile and roof/wall panel roll forming machine: the material thickness range, width range and the profile drawing are required (how many roll forming stations required are depended on the profile drawing); (b) For the slitting line and cut-to-length: the material type (HR, CR, HDGI, PPGI, SS), thickness and width range, coil weight, cutting speed, slitting numbers (only for slitting line), steel plate required cutting length (only for cut-to-length line); (C)For the HVAC machine and the stainless steel pipe machine: the wall thickness range and the diameter range of the pipe; Pls also provide us with your special requirements for the machine, for example, you want the machine to be a full-automatic one or semi-automatic one in order to save your procurement budget. 6. Q: How can we be assured that you will deliver us quality machine with spare parts? A: We usually require our customers to send the technical people to our factory for checking the quality of the machine before shipping. Considering that the buyer usually is not very familiar with the machine assembling and debugging, so we send the technicians to the buyer’s factory for the installation of the machine provided that the Price Term was conclude on ALL IN basis. In addition, we provide all of our customers with the after sales-service; it’s free of charge during the warranty period. 7. Q: Do you have after-sales service? A: Yes, we are happy to give advice and we also have skilled technicians available across the world. We need your machines running in order to keep your business running. During guarantee time, if any parts go broken and not artificial damage, we will send you new ones for free in the warranty period; if the parts were broken caused by the mishandling by the buyers, engineers available to service machinery overseas if the buyers require. But the extal expenses in cluding the charge of visa, the air ticket, the accommodation and traffic fee,etc, will be for the buyer’s account. 8. Q: How do your machines compare with other big companies in this market? A: We are willing to update our products with the latest technology and improve our machines accordingly. 9. Q: How does your factory do regarding quality control? A: Quality is priority. JCX People always attach great importance to quality control from the very beginning to the end of the production. Every product will be fully assembled and carefully tested before it's packed for shipment. 10. Q: Will you deliver the right goods as ordered? How can I trust you? A: Yes, we will. The core of our company culture is honesty and credit. JCX is ALIBAB’s Gold supplier with CE assessment. If you check with ALIBABA, you will see that we have never got any complaint from our customers. Buyer Feedback  Our Certifications Our Certifications We have introduced high standards foreign technologies and management systems and implemented ISO9001:2008 International Quality Management System. Besides, our product have passed the certificate of CE and Rohs, and got the National License of Industrial Product. With many years experiences in R&D and strong technical support, our sales volume grows annually. With excellent quality and competitive price, our products are highly praised by our customers. With the goal of high quality and strong adaptability to the market competition, as well as our ability of R&D for new product in long periods, our products have achieved good market in Asia, European, Africa and America,etc. We sincerely look forward to establishing long-term cooperative relationships with customers from all over the world. OEM and ODM orders are welcomed.

Our Certifications Our Certifications We have introduced high standards foreign technologies and management systems and implemented ISO9001:2008 International Quality Management System. Besides, our product have passed the certificate of CE and Rohs, and got the National License of Industrial Product. With many years experiences in R&D and strong technical support, our sales volume grows annually. With excellent quality and competitive price, our products are highly praised by our customers. With the goal of high quality and strong adaptability to the market competition, as well as our ability of R&D for new product in long periods, our products have achieved good market in Asia, European, Africa and America,etc. We sincerely look forward to establishing long-term cooperative relationships with customers from all over the world. OEM and ODM orders are welcomed.

Contact us if you need more details on Double Layers Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cold Roll Forming Machine、Metal Roofing Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on Double Layers Making Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cold Roll Forming Machine、Metal Roofing Roll Forming Machine. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : Double Layer Roll Forming Machine

Premium Related Products