Automatic change size C Purlin Roll Rolled Forming Machine Made in China

Basic Info

Model No.: c80

Product Description

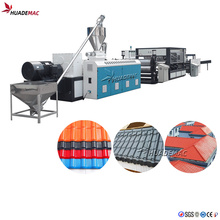

Automatic change size C Purlin Roll Rolled Forming Machine Made in China Our company focus on production and sales of tile press, employ senior technical designers customized for each to come to ordering customers. My company tile press has to the world market platform, received good customer feedback and the second batch of purchase. Specifications Man-made uncoiler-Roll Forming Machine-compture control system-hydraulic control system-form cutter

Material:

Material:

(1)Suitable Coil Thickness: 2.0-3.0 mm

(2)Suitable Raw Materials: Q235 A Machine Components:

(1) Manual Un-coiler 1 set

(2) Leveling Device 1 set

(3) Roll-Forming M/C 1 set

(4) Hydraulic cutting (with four cutting mould) 1 set

(5) PLC Control System 1 set

(6) Product rack (un-powered) 1 set Technical Specification

(1) Manual Un-coiler:

Un-powered; single head; max. Capacity: 3000kg;

Coil inner-diameter: 508mm (2) Leveling Device:

It used for making the material flat before feeding into the roll forming machine. (3) Roll-Forming M/C:

13main steps and 7 auxiliary steps to form; Material of Roller: GCr 15;

It can make all the size of profile in the table through changing the position of the rollers.

Voltage:380V/50Hz Forming speed:0-10m/min; (4) Hydraulic Cutting:

Stop to cut ,Post cut Cutting tool material:Cr12,

tolerance of the cutting length 4mm

It has four cutting mould with the line.

If the customer wants to more cutting mould, he has to pay for the extra moulds. (5) PLC Control System:

Using Mitsubishi PLC Control the quantity, length automatically, LCD screen,

Option Hydraulic un-coiler

Hydraulic system to expand coil inner hole;

Frequency Inverter to regulate turning speed,

Automatic stop device;Load capacity = Max.3Tons; Suitable Material For Production:

C & Z Purlin mainly use hot roll steel strip or hot dip galvanized steel strip at thickness 1.5~3.2mm. it is roll formed by C or Z shape roll forming machine Working Flow:

Decoiling the Sheet—>Sheet Guiding —>Coil Strip Leveling—>Roll Forming—>Punching for

horizontal hole—>Punching for vertical hole —>Measure Length —> Cutting the Panel—>Panels to the Supporter. Product feature and usage:

The products of C or Z shape purline forming machine have excellent anti-bending property and are

easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale

construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on

Material of main equipment: Roller material: high grade NO.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm. Active shaft material: high grade NO.45 carbon wrought steel at diameter 72mm. Cutting blade: Cr12 mould steel with quenched treatment. They are widely used as the roof of garden like factory, hotel, exhibition center, villa, civil construction, etc. Specifications Man-made uncoiler-Roll forming machine-compture control system-hydraulic control system-form cutter

Material of main equipment: Roller material: high grade NO.45 forged steel, plated hard chrome on the surface of roller with thickness 0.05mm. Active shaft material: high grade NO.45 carbon wrought steel at diameter 72mm. Cutting blade: Cr12 mould steel with quenched treatment. They are widely used as the roof of garden like factory, hotel, exhibition center, villa, civil construction, etc. Specifications Man-made uncoiler-Roll forming machine-compture control system-hydraulic control system-form cutter

Material:

Material:

(1)Suitable Coil Thickness: 2.0-3.0 mm

(2)Suitable Raw Materials: Q235 A Machine Components:

(1) Manual Un-coiler 1 set

(2) Leveling Device 1 set

(3) Roll-Forming M/C 1 set

(4) Hydraulic cutting (with four cutting mould) 1 set

(5) PLC Control System 1 set

(6) Product rack (un-powered) 1 set Technical Specification

(1) Manual Un-coiler:

Un-powered; single head; max. Capacity: 3000kg;

Coil inner-diameter: 508mm (2) Leveling Device:

It used for making the material flat before feeding into the roll forming machine. (3) Roll-Forming M/C:

13main steps and 7 auxiliary steps to form; Material of Roller: GCr 15;

It can make all the size of profile in the table through changing the position of the rollers.

Voltage:380V/50Hz Forming speed:0-10m/min; (4) Hydraulic Cutting:

Stop to cut ,Post cut Cutting tool material:Cr12,

tolerance of the cutting length 4mm

It has four cutting mould with the line.

If the customer wants to more cutting mould, he has to pay for the extra moulds. (5) PLC Control System:

Using Mitsubishi PLC Control the quantity, length automatically, LCD screen,

Option Hydraulic un-coiler

Hydraulic system to expand coil inner hole;

Frequency Inverter to regulate turning speed,

Automatic stop device;Load capacity = Max.3Tons; Suitable Material For Production:

C & Z Purlin mainly use hot roll steel strip or hot dip galvanized steel strip at thickness 1.5~3.2mm. it is roll formed by C or Z shape roll forming machine Working Flow:

Decoiling the Sheet—>Sheet Guiding —>Coil Strip Leveling—>Roll Forming—>Punching for

horizontal hole—>Punching for vertical hole —>Measure Length —> Cutting the Panel—>Panels to the Supporter. Product feature and usage:

The products of C or Z shape purline forming machine have excellent anti-bending property and are

easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale

construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on My company welcome you to come to discuss all the way, your trust is our greatest prestige.

My company welcome you to come to discuss all the way, your trust is our greatest prestige.

In product sales, we will be ready for new and old customers to unexpected benefits. Looking forward to receiving your early inquiries ! Contact us if you need more details on C Purlin. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cold Roll Forming Equipment、C Rolling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Material:

Material: (1)Suitable Coil Thickness: 2.0-3.0 mm

(2)Suitable Raw Materials: Q235 A Machine Components:

(1) Manual Un-coiler 1 set

(2) Leveling Device 1 set

(3) Roll-Forming M/C 1 set

(4) Hydraulic cutting (with four cutting mould) 1 set

(5) PLC Control System 1 set

(6) Product rack (un-powered) 1 set Technical Specification

(1) Manual Un-coiler:

Un-powered; single head; max. Capacity: 3000kg;

Coil inner-diameter: 508mm (2) Leveling Device:

It used for making the material flat before feeding into the roll forming machine. (3) Roll-Forming M/C:

13main steps and 7 auxiliary steps to form; Material of Roller: GCr 15;

It can make all the size of profile in the table through changing the position of the rollers.

Voltage:380V/50Hz Forming speed:0-10m/min; (4) Hydraulic Cutting:

Stop to cut ,Post cut Cutting tool material:Cr12,

tolerance of the cutting length 4mm

It has four cutting mould with the line.

If the customer wants to more cutting mould, he has to pay for the extra moulds. (5) PLC Control System:

Using Mitsubishi PLC Control the quantity, length automatically, LCD screen,

Option Hydraulic un-coiler

Hydraulic system to expand coil inner hole;

Frequency Inverter to regulate turning speed,

Automatic stop device;Load capacity = Max.3Tons; Suitable Material For Production:

C & Z Purlin mainly use hot roll steel strip or hot dip galvanized steel strip at thickness 1.5~3.2mm. it is roll formed by C or Z shape roll forming machine Working Flow:

Decoiling the Sheet—>Sheet Guiding —>Coil Strip Leveling—>Roll Forming—>Punching for

horizontal hole—>Punching for vertical hole —>Measure Length —> Cutting the Panel—>Panels to the Supporter. Product feature and usage:

The products of C or Z shape purline forming machine have excellent anti-bending property and are

easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale

construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on

Material:

Material: (1)Suitable Coil Thickness: 2.0-3.0 mm

(2)Suitable Raw Materials: Q235 A Machine Components:

(1) Manual Un-coiler 1 set

(2) Leveling Device 1 set

(3) Roll-Forming M/C 1 set

(4) Hydraulic cutting (with four cutting mould) 1 set

(5) PLC Control System 1 set

(6) Product rack (un-powered) 1 set Technical Specification

(1) Manual Un-coiler:

Un-powered; single head; max. Capacity: 3000kg;

Coil inner-diameter: 508mm (2) Leveling Device:

It used for making the material flat before feeding into the roll forming machine. (3) Roll-Forming M/C:

13main steps and 7 auxiliary steps to form; Material of Roller: GCr 15;

It can make all the size of profile in the table through changing the position of the rollers.

Voltage:380V/50Hz Forming speed:0-10m/min; (4) Hydraulic Cutting:

Stop to cut ,Post cut Cutting tool material:Cr12,

tolerance of the cutting length 4mm

It has four cutting mould with the line.

If the customer wants to more cutting mould, he has to pay for the extra moulds. (5) PLC Control System:

Using Mitsubishi PLC Control the quantity, length automatically, LCD screen,

Option Hydraulic un-coiler

Hydraulic system to expand coil inner hole;

Frequency Inverter to regulate turning speed,

Automatic stop device;Load capacity = Max.3Tons; Suitable Material For Production:

C & Z Purlin mainly use hot roll steel strip or hot dip galvanized steel strip at thickness 1.5~3.2mm. it is roll formed by C or Z shape roll forming machine Working Flow:

Decoiling the Sheet—>Sheet Guiding —>Coil Strip Leveling—>Roll Forming—>Punching for

horizontal hole—>Punching for vertical hole —>Measure Length —> Cutting the Panel—>Panels to the Supporter. Product feature and usage:

The products of C or Z shape purline forming machine have excellent anti-bending property and are

easy to install. They are widely used as the supporter of roof and wall in large-scale and mid-scale

construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on

My company welcome you to come to discuss all the way, your trust is our greatest prestige.

My company welcome you to come to discuss all the way, your trust is our greatest prestige.In product sales, we will be ready for new and old customers to unexpected benefits. Looking forward to receiving your early inquiries ! Contact us if you need more details on C Purlin. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Cold Roll Forming Equipment、C Rolling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : C / Z Profile Roll Forming Machine

Premium Related Products

Other Products

Hot Products

312 ridge cap tile roll forming machineRAL PPGI Steel Coils With Top Coating 15-25um , Back Coating 5-15umNew Type!!Downspout forming machine manufacturerdecoiler roll forming machinefunction color steel sandwich panel made in chinaJCX roll shutter door forming machinearch curving roofing forming machine840/900 Double layer tile making machineJCX stone coated tile machinery made in Chinasand panelHighway Rail making machinefloor deck roll forming machineC/Z purlin roll forming machineCorrugated Tile Steel Roof Cold Roll forming machineGlazed Tile Roll Forming MachineSheet Roll forming machine